Page 601 - Dynamics of Mechanical Systems

P. 601

0593_C17_fm Page 582 Tuesday, May 7, 2002 7:12 AM

582 Dynamics of Mechanical Systems

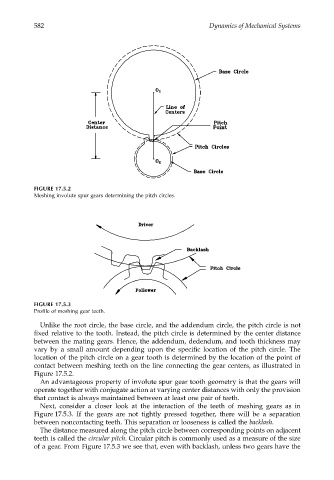

FIGURE 17.5.2

Meshing involute spur gears determining the pitch circles.

FIGURE 17.5.3

Profile of meshing gear teeth.

Unlike the root circle, the base circle, and the addendum circle, the pitch circle is not

fixed relative to the tooth. Instead, the pitch circle is determined by the center distance

between the mating gears. Hence, the addendum, dedendum, and tooth thickness may

vary by a small amount depending upon the specific location of the pitch circle. The

location of the pitch circle on a gear tooth is determined by the location of the point of

contact between meshing teeth on the line connecting the gear centers, as illustrated in

Figure 17.5.2.

An advantageous property of involute spur gear tooth geometry is that the gears will

operate together with conjugate action at varying center distances with only the provision

that contact is always maintained between at least one pair of teeth.

Next, consider a closer look at the interaction of the teeth of meshing gears as in

Figure 17.5.3. If the gears are not tightly pressed together, there will be a separation

between noncontacting teeth. This separation or looseness is called the backlash.

The distance measured along the pitch circle between corresponding points on adjacent

teeth is called the circular pitch. Circular pitch is commonly used as a measure of the size

of a gear. From Figure 17.5.3 we see that, even with backlash, unless two gears have the