Page 602 - Dynamics of Mechanical Systems

P. 602

0593_C17_fm Page 583 Tuesday, May 7, 2002 7:12 AM

Mechanical Components: Gears 583

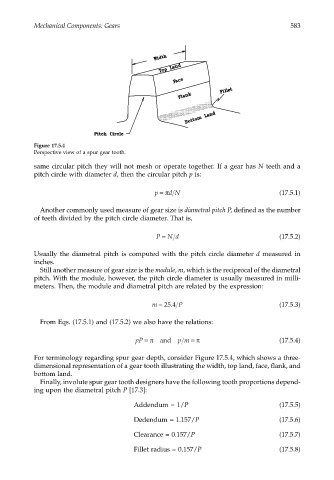

Figure 17.5.4

Perspective view of a spur gear tooth.

same circular pitch they will not mesh or operate together. If a gear has N teeth and a

pitch circle with diameter d, then the circular pitch p is:

p =π d N (17.5.1)

Another commonly used measure of gear size is diametral pitch P, defined as the number

of teeth divided by the pitch circle diameter. That is,

P = N d (17.5.2)

Usually the diametral pitch is computed with the pitch circle diameter d measured in

inches.

Still another measure of gear size is the module, m, which is the reciprocal of the diametral

pitch. With the module, however, the pitch circle diameter is usually measured in milli-

meters. Then, the module and diametral pitch are related by the expression:

m = 25 4 P (17.5.3)

.

From Eqs. (17.5.1) and (17.5.2) we also have the relations:

pP = π and p m = π (17.5.4)

For terminology regarding spur gear depth, consider Figure 17.5.4, which shows a three-

dimensional representation of a gear tooth illustrating the width, top land, face, flank, and

bottom land.

Finally, involute spur gear tooth designers have the following tooth proportions depend-

ing upon the diametral pitch P [17.3]:

Addendum = 1/P (17.5.5)

Dedendum = 1.157/P (17.5.6)

Clearance = 0.157/P (17.5.7)

Fillet radius = 0.157/P (17.5.8)