Page 281 - Electric Drives and Electromechanical Systems

P. 281

278 Electric Drives and Electromechanical Systems

data exchange for applications. The relationship between the OSI and TCP/IP models are

shown in Fig. 11.3.

11.1.4 Industrial specific networking

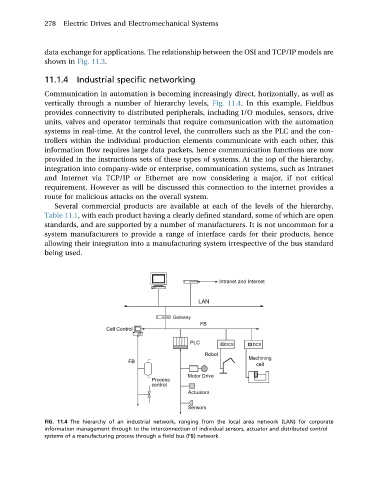

Communication in automation is becoming increasingly direct, horizontally, as well as

vertically through a number of hierarchy levels, Fig. 11.4. In this example, Fieldbus

provides connectivity to distributed peripherals, including I/O modules, sensors, drive

units, valves and operator terminals that require communication with the automation

systems in real-time. At the control level, the controllers such as the PLC and the con-

trollers within the individual production elements communicate with each other, this

information flow requires large data packets, hence communication functions are now

provided in the instructions sets of these types of systems. At the top of the hierarchy,

integration into company-wide or enterprise, communication systems, such as Intranet

and Internet via TCP/IP or Ethernet are now considering a major, if not critical

requirement. However as will be discussed this connection to the internet provides a

route for malicious attacks on the overall system.

Several commercial products are available at each of the levels of the hierarchy,

Table 11.1, with each product having a clearly defined standard, some of which are open

standards, and are supported by a number of manufacturers. It is not uncommon for a

system manufacturers to provide a range of interface cards for their products, hence

allowing their integration into a manufacturing system irrespective of the bus standard

being used.

FIG. 11.4 The hierarchy of an industrial network, ranging from the local area network (LAN) for corporate

information management through to the interconnection of individual sensors, actuator and distributed control

systems of a manufacturing process through a field bus (FB) network.