Page 283 - Electric Drives and Electromechanical Systems

P. 283

280 Electric Drives and Electromechanical Systems

communicates to a central controller over the bus. The closure of the loop over the

bus requires the maintenance of synchronisation, this is achieved by clock cycle

synchronism, where the exchange of data is controlled by a master clock.

11.2 Supervisory control and data acquisition

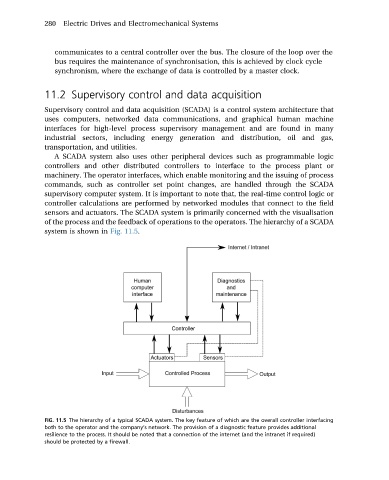

Supervisory control and data acquisition (SCADA) is a control system architecture that

uses computers, networked data communications, and graphical human machine

interfaces for high-level process supervisory management and are found in many

industrial sectors, including energy generation and distribution, oil and gas,

transportation, and utilities.

A SCADA system also uses other peripheral devices such as programmable logic

controllers and other distributed controllers to interface to the process plant or

machinery. The operator interfaces, which enable monitoring and the issuing of process

commands, such as controller set point changes, are handled through the SCADA

supervisory computer system. It is important to note that, the real-time control logic or

controller calculations are performed by networked modules that connect to the field

sensors and actuators. The SCADA system is primarily concerned with the visualisation

of the process and the feedback of operations to the operators. The hierarchy of a SCADA

system is shown in Fig. 11.5.

FIG. 11.5 The hierarchy of a typical SCADA system. The key feature of which are the overall controller interfacing

both to the operator and the company’s network. The provision of a diagnostic feature provides additional

resilience to the process. It should be noted that a connection of the internet (and the intranet if required)

should be protected by a firewall.