Page 220 - Electrical Equipment Handbook _ Troubleshooting and Maintenance

P. 220

VARIABLE-SPEED DRIVES

VARIABLE-SPEED DRIVES 10.19

Drive Stator Rotor

C sr

Line to Neutral

Sources R b

C sf C rf

C b Z b

Zero Sequence

Source

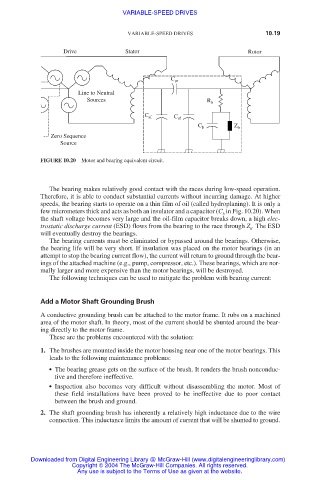

FIGURE 10.20 Motor and bearing equivalent circuit.

The bearing makes relatively good contact with the races during low-speed operation.

Therefore, it is able to conduct substantial currents without incurring damage. At higher

speeds, the bearing starts to operate on a thin film of oil (called hydroplaning). It is only a

few micrometers thick and acts as both an insulator and a capacitor (C in Fig. 10.20). When

b

the shaft voltage becomes very large and the oil-film capacitor breaks down, a high elec-

trostatic discharge current (ESD) flows from the bearing to the race through Z . The ESD

b

will eventually destroy the bearings.

The bearing currents must be eliminated or bypassed around the bearings. Otherwise,

the bearing life will be very short. If insulation was placed on the motor bearings (in an

attempt to stop the bearing current flow), the current will return to ground through the bear-

ings of the attached machine (e.g., pump, compressor, etc.). These bearings, which are nor-

mally larger and more expensive than the motor bearings, will be destroyed.

The following techniques can be used to mitigate the problem with bearing current:

Add a Motor Shaft Grounding Brush

A conductive grounding brush can be attached to the motor frame. It rubs on a machined

area of the motor shaft. In theory, most of the current should be shunted around the bear-

ing directly to the motor frame.

These are the problems encountered with the solution:

1. The brushes are mounted inside the motor housing near one of the motor bearings. This

leads to the following maintenance problems:

● The bearing grease gets on the surface of the brush. It renders the brush nonconduc-

tive and therefore ineffective.

● Inspection also becomes very difficult without disassembling the motor. Most of

these field installations have been proved to be ineffective due to poor contact

between the brush and ground.

2. The shaft grounding brush has inherently a relatively high inductance due to the wire

connection. This inductance limits the amount of current that will be shunted to ground.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.