Page 131 - Electromechanical Devices and Components Illustrated Sourcebook

P. 131

Chapter 5 Magnetic Components 93

High-Voltage Terminal Core Secondary

Insulator Terminals

Label

Case

Primary

Terminals

115/120 VAC, 50/60 Hz Input Terminals Compensation

Coil

Mount Tabs

Mount Tabs

Figure 5-34 Neon Light Transformer

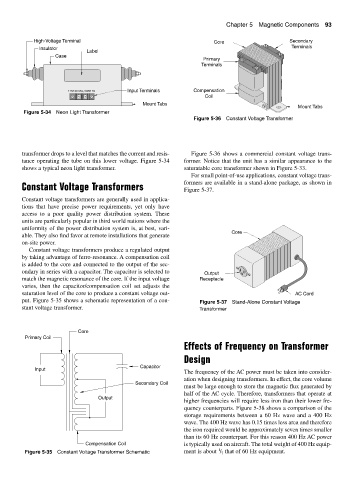

Figure 5-36 Constant Voltage Transformer

transformer drops to a level that matches the current and resis- Figure 5-36 shows a commercial constant voltage trans-

tance operating the tube on this lower voltage. Figure 5-34 former. Notice that the unit has a similar appearance to the

shows a typical neon light transformer. saturatable core transformer shown in Figure 5-33.

For small point-of-use applications, constant voltage trans-

formers are available in a stand-alone package, as shown in

Constant Voltage Transformers Figure 5-37.

Constant voltage transformers are generally used in applica-

tions that have precise power requirements, yet only have

access to a poor quality power distribution system. These

units are particularly popular in third world nations where the

uniformity of the power distribution system is, at best, vari-

Core

able. They also find favor at remote installations that generate

on-site power.

Constant voltage transformers produce a regulated output

by taking advantage of ferro-resonance. A compensation coil

is added to the core and connected to the output of the sec-

ondary in series with a capacitor. The capacitor is selected to Output

match the magnetic resonance of the core. If the input voltage Receptacle

varies, then the capacitor/compensation coil set adjusts the

saturation level of the core to produce a constant voltage out- AC Cord

put. Figure 5-35 shows a schematic representation of a con- Figure 5-37 Stand-Alone Constant Voltage

stant voltage transformer. Transformer

Core

Primary Coil

Effects of Frequency on Transformer

Design

Capacitor

Input

The frequency of the AC power must be taken into consider-

ation when designing transformers. In effect, the core volume

Secondary Coil

must be large enough to store the magnetic flux generated by

half of the AC cycle. Therefore, transformers that operate at

Output

higher frequencies will require less iron than their lower fre-

quency counterparts. Figure 5-38 shows a comparison of the

storage requirements between a 60 Hz wave and a 400 Hz

wave. The 400 Hz wave has 0.15 times less area and therefore

the iron required would be approximately seven times smaller

than its 60 Hz counterpart. For this reason 400 Hz AC power

Compensation Coil is typically used on aircraft. The total weight of 400 Hz equip-

1

Figure 5-35 Constant Voltage Transformer Schematic ment is about / that of 60 Hz equipment.

7