Page 135 - Electromechanical Devices and Components Illustrated Sourcebook

P. 135

Chapter 5 Magnetic Components 97

Laminated "E" Core 100

Laminated "T"

Percent of Max. Force 50

Plunger

Rivets 75

Bolt Lug Terminals

Coil 25

0

0 20 40 60 80 100

Mounting Flanges

Percent of Max. Extension

Figure 5-50 Laminated Core AC Solenoid

Figure 5-52 Solenoid Force Profile

coil is designed to operate on AC power. These units are man-

ufactured in particularly large sizes that can produce hundreds Solenoid

of pounds of force. Figure 5-50 shows a commercial lami-

nated core AC solenoid. Air Cylinder

Cylindrical solenoids are used extensively for applications

that do not require particularly high force. They are typically

small units that have an integral nose mount. They will usu- Check Valve

ally have two wires as their terminals and are available in AC Needle Valve

or DC versions. Figure 5-51 shows a commercial cylindrical

Figure 5-53 Damping Solenoid Motion

solenoid.

Mounting Nose Coil Housing Coil

Iron Rod Plastic Tube

Plunger

Bolt Lug

Terminals

Terminal

Wires Figure 5-54 Bench Built Solenoid

Figure 5-51 Cylindrical Solenoid

inserted in the center. When the coil is connected to a battery,

the core will be pulled into the center of the core.

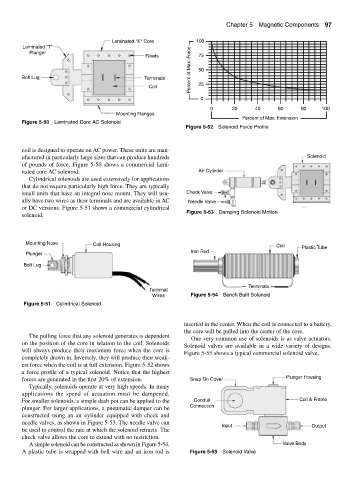

The pulling force that any solenoid generates is dependent

One very common use of solenoids is as valve actuators.

on the position of the core in relation to the coil. Solenoids

Solenoid valves are available in a wide variety of designs.

will always produce their maximum force when the core is

Figure 5-55 shows a typical commercial solenoid valve.

completely drawn in. Inversely, they will produce their weak-

est force when the coil is at full extension. Figure 5-52 shows

a force profile of a typical solenoid. Notice that the highest

forces are generated in the first 20% of extension. Snap On Cover Plunger Housing

Typically, solenoids operate at very high speeds. In many

applications the speed of actuation must be dampened.

For smaller solenoids, a simple dash pot can be applied to the Conduit Coil & Frame

plunger. For larger applications, a pneumatic damper can be Connection

constructed using an air cylinder equipped with check and

needle valves, as shown in Figure 5-53. The needle valve can

Input Output

be used to control the rate at which the solenoid retracts. The

check valve allows the core to extend with no restriction.

A simple solenoid can be constructed as shown in Figure 5-54. Valve Body

A plastic tube is wrapped with bell wire and an iron rod is Figure 5-55 Solenoid Valve