Page 177 - Electromechanical Devices and Components Illustrated Sourcebook

P. 177

Chapter 8 Circuit Protection 139

Long Throw Interrupters Fixed Contact Moving Contact

Figure 8-13 shows a fast acting, long throw interrupter. The

unit has a moving contact that is spring loaded for fast open-

Open

ing. When the trigger is pressed, the moving contact is pulled

into the open position. The distance between the contacts is

too wide to allow the arc to sustain. The speed at which the

contact retracts limits the duration of the arc and mitigates the

Vacuum Bellows

damage that it causes. Long throw interrupters are only prac- Metal Vapor Shield

tical to a certain upper limit. As the voltages become higher, Contacts Flange

the size and speed of these units becomes a factor. Ceramic Insulator

Closed Terminal

Vacuum

Vessel Copper

Terminal O-Ring

Flexible Cable

Figure 8-14 Vacuum Interrupter

Latch

Retract Spring

Terminal Trigger

from the contacts. Figure 8-15 shows a typical pneumatic

Bronze Bushing

suppression interrupter. The contacts are built into a pair of

Insulating Column

Moving Contact bolted clam shells. A diaphragm is sandwiched between the

Moving Rod

flanges. The center of the diaphragm is fixed to the moving

Preload Spring

Fixed Contact contact. When the contacts are opened, the cavity behind the

Contacts diaphragm is pressurized and a jet of gas is forced through the

Terminal center orifice. The gas jet blows the arc away from the con-

Open Closed

tacts and it is extinguished. To improve the performance of

Figure 8-13 Fast Acting, Long Throw Interrupter

these interrupters, the air can be replaced with a gas having a

higher dielectric, such as sulfurhexifloride.

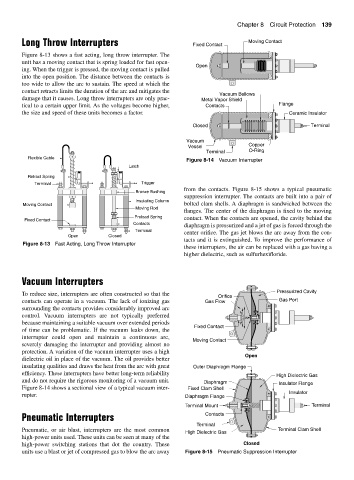

Vacuum Interrupters

To reduce size, interrupters are often constructed so that the Pressurized Cavity

Orifice

contacts can operate in a vacuum. The lack of ionizing gas Gas Flow Gas Port

surrounding the contacts provides considerably improved arc

control. Vacuum interrupters are not typically preferred

because maintaining a suitable vacuum over extended periods

Fixed Contact

of time can be problematic. If the vacuum leaks down, the

interrupter could open and maintain a continuous arc,

Moving Contact

severely damaging the interrupter and providing almost no

protection. A variation of the vacuum interrupter uses a high

Open

dielectric oil in place of the vacuum. The oil provides better

insulating qualities and draws the heat from the arc with great Outer Diaphragm Flange

efficiency. These interrupters have better long-term reliability High Dielectric Gas

and do not require the rigorous monitoring of a vacuum unit. Diaphragm Insulator Flange

Figure 8-14 shows a sectional view of a typical vacuum inter- Fixed Clam Shell

Insulator

rupter. Diaphragm Flange

Terminal Mount Terminal

Pneumatic Interrupters Contacts

Terminal

Pneumatic, or air blast, interrupters are the most common Terminal Clam Shell

High Dielectric Gas

high-power units used. These units can be seen at many of the

high-power switching stations that dot the country. These Closed

units use a blast or jet of compressed gas to blow the arc away Figure 8-15 Pneumatic Suppression Interrupter