Page 178 - Electromechanical Devices and Components Illustrated Sourcebook

P. 178

140 Electromechanical Devices & Components Illustrated Sourcebook

Magnetic Arc Suppression Heat

Smaller applications, such as motor contactors, will often

incorporate magnetic arc suppression. In this arrangement the

arc is exposed to a perpendicular magnetic field, as shown in Opened

(Tripped)

Figure 8-16. As the arc forms, the magnetic field forces it into Open Contacts

a long, curved path and the arc extinguishes.

Axle Housing Induction Coil (Heater)

Axle

Serrated Wheel Solder Head

Reset Button

Arc

Motor Terminals

Contacts Housing Mount

Switch Terminals

Terminals

Ratchet Rack

Closed Contacts

Trip Spring Closed

Magnetic Blowout Coil

(Operate)

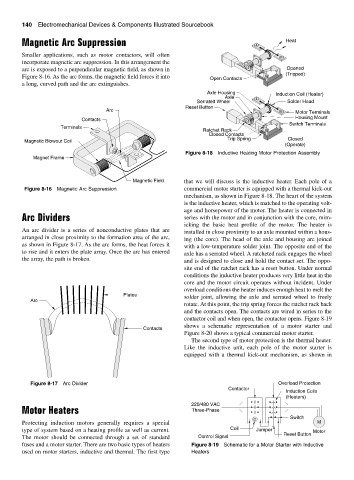

Figure 8-18 Inductive Heating Motor Protection Assembly

Magnet Frame

Magnetic Field that we will discuss is the inductive heater. Each pole of a

Figure 8-16 Magnetic Arc Suppression commercial motor starter is equipped with a thermal kick-out

mechanism, as shown in Figure 8-18. The heart of the system

is the inductive heater, which is matched to the operating volt-

age and horsepower of the motor. The heater is connected in

Arc Dividers series with the motor and in conjunction with the core, mim-

icking the basic heat profile of the motor. The heater is

An arc divider is a series of nonconductive plates that are installed in close proximity to an axle mounted within a hous-

arranged in close proximity to the formation area of the arc, ing (the core). The head of the axle and housing are joined

as shown in Figure 8-17. As the arc forms, the heat forces it with a low-temperature solder joint. The opposite end of the

to rise and it enters the plate array. Once the arc has entered axle has a serrated wheel. A ratcheted rack engages the wheel

the array, the path is broken. and is designed to close and hold the contact set. The oppo-

site end of the ratchet rack has a reset button. Under normal

conditions the inductive heater produces very little heat in the

core and the motor circuit operates without incident. Under

overload conditions the heater induces enough heat to melt the

Plates solder joint, allowing the axle and serrated wheel to freely

Arc

rotate. At this point, the trip spring forces the ratchet rack back

and the contacts open. The contacts are wired in series to the

contactor coil and when open, the contactor opens. Figure 8-19

shows a schematic representation of a motor starter and

Contacts

Figure 8-20 shows a typical commercial motor starter.

The second type of motor protection is the thermal heater.

Like the inductive unit, each pole of the motor starter is

equipped with a thermal kick-out mechanism, as shown in

Figure 8-17 Arc Divider Overload Protection

Contactor

Induction Coils

(Heaters)

220/480 VAC

Motor Heaters Three-Phase

Switch

C

Protecting induction motors generally requires a special M

type of system based on a heating profile as well as current. Coil Jumper Motor

Reset Button

The motor should be connected through a set of standard Control Signal

fuses and a motor starter. There are two basic types of heaters Figure 8-19 Schematic for a Motor Starter with Inductive

used on motor starters, inductive and thermal. The first type Heaters