Page 179 - Electromechanical Devices and Components Illustrated Sourcebook

P. 179

Chapter 8 Circuit Protection 141

Contactor Overload Protection

Contactor

Heaters

Reset Button

220/480 VAC

Heaters Three-Phase

Coil

Terminals C

Overload M

Protector

Coil Jumper Switch Motor

Jumper Control Signal

Base

Figure 8-22 Schematic for a Motor Starter with Thermal

Heaters

Switch Terminals

Figure 8-20 Commercial Motor Starter

Power Input Contactor

Motor Terminals Heaters

Motor Terminals

Contacts Heating Element

Bimetal Strip

Closed

(Operate) Coil Terminals

Switch Terminals Figure 8-23 Commercial Motor Starter with Integral Thermal

Heater Protection

Heat

Open

(Over Load)

Switch Neon Lamp

Figure 8-21 Thermal Heating Motor Protection Assembly

M

Power Source Load

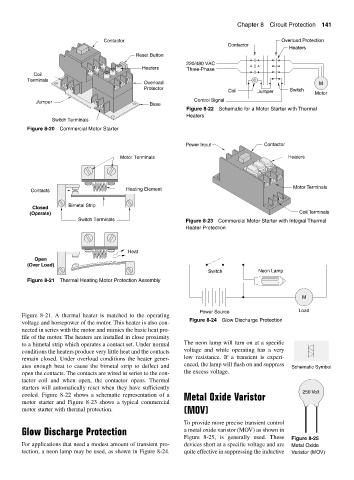

Figure 8-21. A thermal heater is matched to the operating

Figure 8-24 Glow Discharge Protection

voltage and horsepower of the motor. This heater is also con-

nected in series with the motor and mimics the basic heat pro-

file of the motor. The heaters are installed in close proximity

to a bimetal strip which operates a contact set. Under normal The neon lamp will turn on at a specific

conditions the heaters produce very little heat and the contacts voltage and while operating has a very

remain closed. Under overload conditions the heater gener- low resistance. If a transient is experi-

ates enough heat to cause the bimetal strip to deflect and enced, the lamp will flash on and suppress Schematic Symbol

open the contacts. The contacts are wired in series to the con- the excess voltage.

tactor coil and when open, the contactor opens. Thermal

starters will automatically reset when they have sufficiently

250 Volt

cooled. Figure 8-22 shows a schematic representation of a Metal Oxide Varistor

motor starter and Figure 8-23 shows a typical commercial

motor starter with thermal protection. (MOV)

To provide more precise transient control

Glow Discharge Protection a metal oxide varistor (MOV) as shown in

Figure 8-25, is generally used. These Figure 8-25

For applications that need a modest amount of transient pro- devices short at a specific voltage and are Metal Oxide

tection, a neon lamp may be used, as shown in Figure 8-24. quite effective in suppressing the inductive Varistor (MOV)