Page 309 - Electromechanical Devices and Components Illustrated Sourcebook

P. 309

Chapter 15 Sensors 271

contacts. The detector is located in the bottom of the equip- up and through the filter element. In the event the filter

ment’s oil sump where it slowly collects ferrous particles. When becomes clogged, a bypass loop is generally incorporated into

enough particles have been collected, the contacts become con- the design. The idea being that it is better to get unfiltered oil

ductive and alert the operator that a critical condition exists. than no oil at all. The bypass loop is usually a spring-loaded

disk valve that will open if the suction becomes too great. By

extending the disk valve shaft out of the bypass loop, a limit

Light Spectrometer switch can be activated. If the disk valve opens, then the limit

A simple light spectrometer can be configured by using an switch closes and the indicator lamp turns on.

array of opto-sensors and an ordinary prism, as shown in

Figure 15-89. A senor like this can be used to gauge the per-

formance of all sorts of light sources. As an example, the light

emitted by an ordinary spark plug can indicate surface condi-

Indicator

tion, gap, contamination, voltage, and the like. Oil can be

Lamp

gauged by creating a spark through a film of the oil and study-

ing the light spectrum that it produces. L Limit Switch

Preload Spring

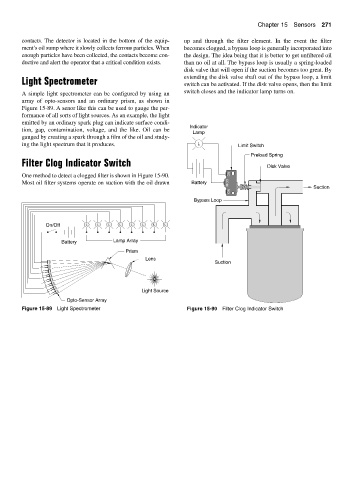

Filter Clog Indicator Switch Disk Valve

One method to detect a clogged filter is shown in Figure 15-90. NC

Most oil filter systems operate on suction with the oil drawn Battery COM

Suction

NO

Bypass Loop

On/Off L L L L L L L L

Battery Lamp Array

Prism

Lens

Suction

Light Source

Opto-Sensor Array

Figure 15-89 Light Spectrometer Figure 15-90 Filter Clog Indicator Switch