Page 308 - Electromechanical Devices and Components Illustrated Sourcebook

P. 308

270 Electromechanical Devices & Components Illustrated Sourcebook

measure the time it takes for a known weight to fall through a

column of liquid. The set up shown uses a graduated cylinder Force

placed on an ordinary laboratory stand. A weighted rod with

a paddle on one end is suspended in the center of the cylinder.

The rod is pulled up and held in place by a solenoid-operated

brake assembly. The solenoid and a limit switch communicate

Steel Frame

with an ordinary laboratory timer. When the start button on

the timer is pressed, the solenoid releases the brake and the rod

Strain Gauge Element

starts to fall at the same instant the timer starts. When the rod

reaches the bottom, it trips the limit switch, which turns off

the timer. By gauging the displayed time, the viscosity of the

fluid can be determined.

Load Cells

Measuring force has far reaching applications, from gauging Connector

the load on a crane, to accurately applying a torque to a fas- Figure 15-86 S-Type Load Cell

tener. Until the advent of load cells, mechanical scales were

the only real method for measuring force. Mechanical scales

have been all but replaced by the used of load cells. Through Hole

Figure 15-85 shows a typical load cell schematic. The load

cell is some sort of frame that mounts a strain gauge element Steel Washer

in a fashion that allows a micro amount of flexure if a load is

placed on the device. In the case of the illustration, as a

Strain Gauge Element

pulling force is applied to the length of the frame, it has a ten-

dency to stretch. The element is placed at a bridging point of Steel Washer

an asymmetric cutout, which is designed to introduce a shear

load to the gauge. As the element changes shape, its resistance

changes in direct proportion to the amount of force being

Output

applied. The gauge is set up as one element of a Wheatstone

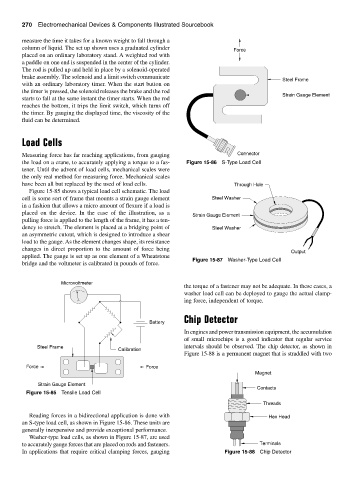

Figure 15-87 Washer-Type Load Cell

bridge and the voltmeter is calibrated in pounds of force.

Microvoltmeter

the torque of a fastener may not be adequate. In these cases, a

washer load cell can be deployed to gauge the actual clamp-

ing force, independent of torque.

Chip Detector

Battery

In engines and power transmission equipment, the accumulation

of small microchips is a good indicator that regular service

Steel Frame intervals should be observed. The chip detector, as shown in

Calibration

Figure 15-88 is a permanent magnet that is straddled with two

Force Force

Magnet

Strain Gauge Element

Contacts

Figure 15-85 Tensile Load Cell

Threads

Reading forces in a bidirectional application is done with Hex Head

an S-type load cell, as shown in Figure 15-86. These units are

generally inexpensive and provide exceptional performance.

Washer-type load cells, as shown in Figure 15-87, are used

to accurately gauge forces that are placed on rods and fasteners. Terminals

In applications that require critical clamping forces, gauging Figure 15-88 Chip Detector