Page 316 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 316

P1: GLQ Final pages

Encyclopedia of Physical Science and Technology En007c-310 June 30, 2001 17:30

262 Heat Exchangers

the actual value of the exchanger in the process. Also,

at this point the single most important decision is made

(often by default): what basic configuration of exchanger

is to be chosen and designed? In the process industries

the usual answer is the shell-and-tube exchanger, but it is

always worth reviewing the other possibilities.

The next decision is what design method is to be used.

Basically, these fall into two categories: hand design and

computer design. Hand design methods in the most recent

literature and applied by a competent designer are still

valid for a large fraction of all heat exchanger problems.

If one chooses to use a computer design method, there is

still the task of selecting the level of the method. There are

short-cut and detailed computer design methods available

for most exchanger types.

The next step is to select a tentative set of exchanger

geometric parameters. The better the starting design, the

sooner the designer will come to the final design, and

this is very important for hand calculation methods. On a

computer, however, it is usually faster to give the computer

a very conservative (oversized) starting point and use its

enormouscomputationalspeedtomovetowardthedesired

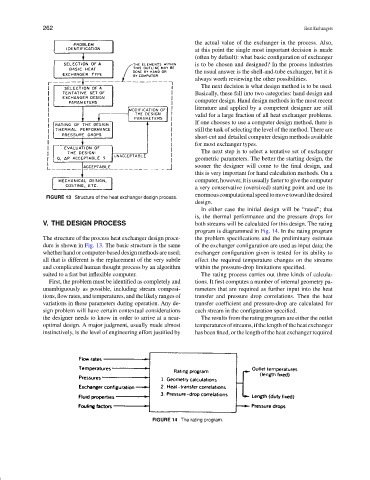

FIGURE 13 Structure of the heat exchanger design process.

design.

In either case the initial design will be “rated”; that

is, the thermal performance and the pressure drops for

V. THE DESIGN PROCESS both streams will be calculated for this design. The rating

program is diagrammed in Fig. 14. In the rating program

The structure of the process heat exchanger design proce- the problem specifications and the preliminary estimate

dure is shown in Fig. 13. The basic structure is the same of the exchanger configuration are used as input data; the

whether hand or computer-based design methods are used; exchanger configuration given is tested for its ability to

all that is different is the replacement of the very subtle effect the required temperature changes on the streams

and complicated human thought process by an algorithm within the pressure-drop limitations specified.

suited to a fast but inflexible computer. The rating process carries out three kinds of calcula-

First, the problem must be identified as completely and tions. It first computes a number of internal geometry pa-

unambiguously as possible, including stream composi- rameters that are required as further input into the heat

tions, flow rates, and temperatures, and the likely ranges of transfer and pressure drop correlations. Then the heat

variations in these parameters during operation. Any de- transfer coefficient and pressure-drop are calculated for

sign problem will have certain contextual considerations each stream in the configuration specified.

the designer needs to know in order to arrive at a near- The results from the rating program are either the outlet

optimal design. A major judgment, usually made almost temperaturesof streams, if the length of the heat exchanger

instinctively, is the level of engineering effort justified by has been fixed, or the length of the heat exchanger required

FIGURE 14 The rating program.