Page 313 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 313

P1: GLQ Final pages

Encyclopedia of Physical Science and Technology En007c-310 June 30, 2001 17:30

Heat Exchangers 259

axial-flow fan is the most effective way to move these vol-

umes of air, but it is only capable of very small pressure

rises, on the order of 150–500 Pa, with the lower figure

being a common design value. The low allowable pres-

sure drop means that the air must be moved very slowly

(around 3 m/s) and that the tube field must be shallow (3–

12 rows of tubes) and very broad to accommodate the high

volumetric flow requirements. This is turn results in low

heat transfer coefficients on the air side (about 60 W/m K).

As will be seen in a later section, it is desirable to pro-

vide “extended surface” or fins on an outer tube surface

that is in contact with a fluid having a low heat transfer co-

efficient when the fluid inside the tube has a much higher

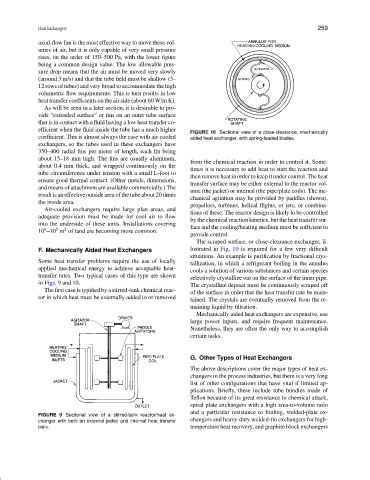

FIGURE 10 Sectional view of a close-clearance, mechanically

coefficient. This is almost always the case with air-cooled aided heat exchanger, with spring-loaded blades.

exchangers, so the tubes used in these exchangers have

350–400 radial fins per meter of length, each fin being

about 15–18 mm high. The fins are usually aluminum,

from the chemical reaction in order to control it. Some-

about 0.4 mm thick, and wrapped continuously on the

times it is necessary to add heat to start the reaction and

tube circumference under tension with a small L-foot to

then remove heat in order to keep it under control. The heat

ensure good thermal contact. (Other metals, dimensions,

transfer surface may be either external to the reactor vol-

and means of attachment are available commercially.) The

ume (the jacket) or internal (the pipe/plate coils). The me-

result is an effective outside area of the tube about 20 times

chanical agitation may be provided by paddles (shown),

the inside area.

propellors, turbines, helical flights, or jets, or combina-

Air-cooled exchangers require large plan areas, and

tions of these. The reactor design is likely to be controlled

adequate provision must be made for cool air to flow

by the chemical reaction kinetics, but the heat transfer sur-

into the underside of these units. Installations covering face and the cooling/heating medium must be sufficient to

5

2

4

10 –10 m of land are becoming more common.

provide control.

The scraped surface, or close-clearance exchanger, il-

F. Mechanically Aided Heat Exchangers lustrated in Fig. 10 is required for a few very difficult

situations. An example is purification by fractional crys-

Some heat transfer problems require the use of locally

tallization, in which a refrigerant boiling in the annulus

applied mechanical energy to achieve acceptable heat-

cools a solution of various substances and certain species

transfer rates. Two typical cases of this type are shown

selectively crystallize out on the surface of the inner pipe.

in Figs. 9 and 10. The crystalline deposit must be continuously scraped off

The first case is typified by a stirred-tank chemical reac- of the surface in order that the heat transfer rate be main-

tor in which heat must be externally added to or removed tained. The crystals are eventually removed from the re-

maining liquid by filtration.

Mechanically aided heat exchangers are expensive, use

large power inputs, and require frequent maintenance.

Nonetheless, they are often the only way to accomplish

certain tasks.

G. Other Types of Heat Exchangers

The above descriptions cover the major types of heat ex-

changers in the process industries, but there is a very long

list of other configurations that have vital if limited ap-

plications. Briefly, these include tube bundles made of

Teflon because of its great resistance to chemical attack,

spiral plate exchangers with a high area-to-volume ratio

and a particular resistance to fouling, welded-plate ex-

FIGURE 9 Sectional view of a stirred-tank reactor/heat ex-

changer with both an external jacket and internal heat transfer changers and heavy-duty welded-fin exchangers for high-

coils. temperature heat recovery, and graphite block exchangers