Page 368 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 368

P1: GLQ Final Pages

Encyclopedia of Physical Science and Technology EN009K-419 July 19, 2001 20:57

Membranes, Synthetic, Applications 303

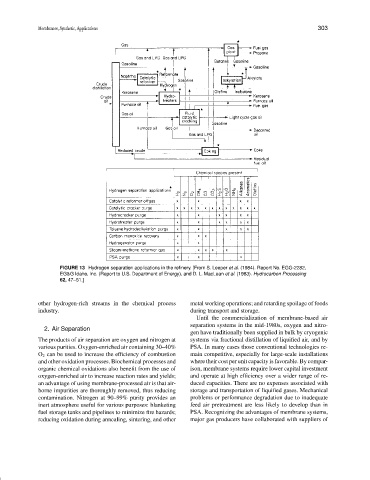

FIGURE 13 Hydrogen separation applications in the refinery. [From S. Leeper et al. (1984). Report No. EGG-2282,

EG&G Idaho, Inc. (Report to U.S. Department of Energy), and D. L. MacLean et al. (1983). Hydrocarbon Processing

62, 47–51.]

other hydrogen-rich streams in the chemical process metal working operations; and retarding spoilage of foods

industry. during transport and storage.

Until the commercialization of membrane-based air

separation systems in the mid-1980s, oxygen and nitro-

2. Air Separation

gen have traditionally been supplied in bulk by cryogenic

The products of air separation are oxygen and nitrogen at systems via fractional distillation of liquified air, and by

various purities. Oxygen-enriched air containing 30–40% PSA. In many cases those conventional technologies re-

O 2 can be used to increase the efficiency of combustion main competitive, especially for large-scale installations

and other oxidation processes. Biochemical processes and where their cost per unit capacity is favorable. By compar-

organic chemical oxidations also benefit from the use of ison, membrane systems require lower capital investment

oxygen-enriched air to increase reaction rates and yields; and operate at high efficiency over a wider range of re-

an advantage of using membrane-processed air is that air- duced capacities. There are no expenses associated with

borne impurities are thoroughly removed, thus reducing storage and transportation of liquified gases. Mechanical

contamination. Nitrogen at 90–99% purity provides an problems or performance degradation due to inadequate

inert atmosphere useful for various purposes: blanketing feed air pretreatment are less likely to develop than in

fuel storage tanks and pipelines to minimize fire hazards; PSA. Recognizing the advantages of membrane systems,

reducing oxidation during annealing, sintering, and other major gas producers have collaborated with suppliers of