Page 373 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 373

P1: GLQ Final Pages

Encyclopedia of Physical Science and Technology EN009K-419 July 19, 2001 20:57

308 Membranes, Synthetic, Applications

TABLE VI Guidelines for Membrane Selection in Gas-Vapor Separations (Baker et al., 1998)

Gas-selective membrane Vapor-selective membrane

Configuration C 3 H 8 /N 2 N 2

C 3 H 8 /N 2 C 3 H 8

N 2 C 3 H 8

Membrane Rigid, glassy, amorphous (e.g., polysulfone) Soft, rubbery (e.g., silicone rubber)

Typical nitrogen permeation flux 1–10 100–1000

2

3

(10 −6 cm (STP)/cm sec cm Hg)

Typical separations H 2 /N 2 , O 2 /N 2 , CO 2 /CH 4 Volatile organic compounds/air, C 3 H 8 /N 2

to the reactor. Conversely, using a membrane more perme- librium. However, if the liquid is bound by a nonporous

able to the inert gas can yield a reactant stream at pressure, membrane, then the rate of vaporization of each compo-

reducing or eliminating the need for recompression dur- nent is limited by the permeability of the membrane. This

ing recycle. Some general guidelines required for practical membrane-mediated evaporation process is referred to as

application of these two strategies are given in Table VI pervaporation. By providing a partial vacuum or by circu-

(Baker et al., 1998). Attractive applications have been im- lating a noncondensing sweep gas on the downstream side

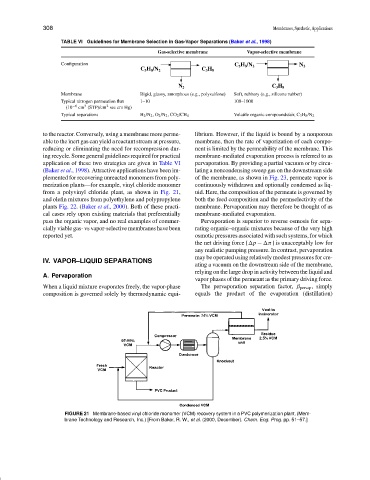

plemented for recovering unreacted monomers from poly- of the membrane, as shown in Fig. 23, permeate vapor is

merization plants—for example, vinyl chloride monomer continuously withdrawn and optionally condensed as liq-

from a polyvinyl chloride plant, as shown in Fig. 21, uid. Here, the composition of the permeate is governed by

and olefin mixtures from polyethylene and polypropylene both the feed composition and the permselectivity of the

plants Fig. 22. (Baker et al., 2000). Both of these practi- membrane. Pervaporation may therefore be thought of as

cal cases rely upon existing materials that preferentially membrane-mediated evaporation.

pass the organic vapor, and no real examples of commer- Pervaporation is superior to reverse osmosis for sepa-

cially viable gas- vs vapor-selective membranes have been rating organic–organic mixtures because of the very high

reported yet. osmotic pressures associated with such systems, for which

the net driving force [

p −

π] is unacceptably low for

any realistic pumping pressure. In contrast, pervaporation

may be operated using relatively modest pressures for cre-

IV. VAPOR–LIQUID SEPARATIONS

ating a vacuum on the downstream side of the membrane,

relying on the large drop in activity between the liquid and

A. Pervaporation

vapor phases of the permeant as the primary driving force.

When a liquid mixture evaporates freely, the vapor-phase The pervaporation separation factor, β pervap , simply

composition is governed solely by thermodynamic equi- equals the product of the evaporation (distillation)

FIGURE 21 Membrane-based vinyl chloride monomer (VCM) recovery system in a PVC polymerization plant. (Mem-

brane Technology and Research, Inc.) [From Baker, R. W., et al. (2000, December). Chem. Eng. Prog. pp. 51–57.]