Page 374 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 374

P1: GLQ Final Pages

Encyclopedia of Physical Science and Technology EN009K-419 July 19, 2001 20:57

Membranes, Synthetic, Applications 309

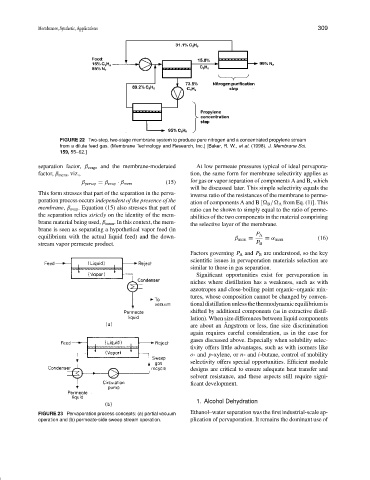

FIGURE 22 Two-step, two-stage membrane system to produce pure nitrogen and a concentrated propylene stream

from a dilute feed gas. (Membrane Technology and Research, Inc.) [Baker, R. W., et al. (1998). J. Membrane Sci.

159, 55–62.]

separation factor, β evap , and the membrane-moderated At low permeate pressures typical of ideal pervapora-

factor, β mem , viz., tion, the same form for membrane selectivity applies as

β pervap = β evap · β mem (15) for gas or vapor separation of components A and B, which

will be discussed later. This simple selectivity equals the

This form stresses that part of the separation in the perva- inverse ratio of the resistances of the membrane to perme-

poration process occurs independent of the presence of the ation of components A and B [ B / A from Eq. (1)]. This

membrane, β evap . Equation (15) also stresses that part of ratio can be shown to simply equal to the ratio of perme-

the separation relies strictly on the identity of the mem- abilities of the two components in the material comprising

brane material being used, β mem . In this context, the mem- the selective layer of the membrane.

brane is seen as separating a hypothetical vapor feed (in

equilibrium with the actual liquid feed) and the down- β mem = P A = α mem (16)

stream vapor permeate product. P B

Factors governing P A and P B are understood, so the key

scientific issues in pervaporation materials selection are

similar to those in gas separation.

Significant opportunities exist for pervaporation in

niches where distillation has a weakness, such as with

azeotropes and close-boiling point organic–organic mix-

tures, whose composition cannot be changed by conven-

tional distillation unless the thermodynamic equilibrium is

shifted by additional components (as in extractive distil-

lation). When size differences between liquid components

˚

are about an Angstrom or less, fine size discrimination

again requires careful consideration, as in the case for

gases discussed above. Especially when solubility selec-

tivity offers little advantages, such as with isomers like

o- and p-xylene, or n- and i-butane, control of mobility

selectivity offers special opportunities. Efficient module

designs are critical to ensure adequate heat transfer and

solvent resistance, and these aspects still require signi-

ficant development.

1. Alcohol Dehydration

FIGURE 23 Pervaporation process concepts: (a) partial vacuum Ethanol–water separation was the first industrial-scale ap-

operation and (b) permeate-side sweep stream operation. plication of pervaporation. It remains the dominant use of