Page 376 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 376

P1: GLQ Final Pages

Encyclopedia of Physical Science and Technology EN009K-419 July 19, 2001 20:57

Membranes, Synthetic, Applications 311

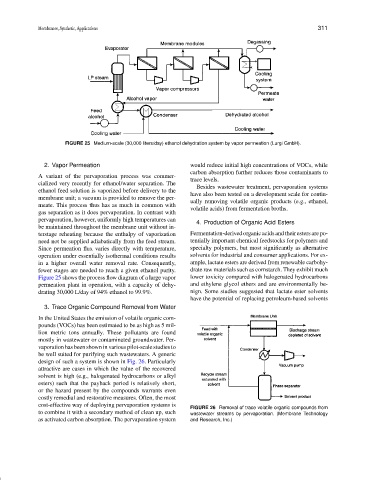

FIGURE 25 Medium-scale (30,000 liters/day) ethanol dehydration system by vapor permeation (Lurgi GmbH).

2. Vapor Permeation would reduce initial high concentrations of VOCs, while

carbon absorption further reduces those contaminants to

A variant of the pervaporation process was commer-

trace levels.

cialized very recently for ethanol/water separation. The

Besides wastewater treatment, pervaporation systems

ethanol feed solution is vaporized before delivery to the

have also been tested on a development scale for contin-

membrane unit; a vacuum is provided to remove the per-

ually removing volatile organic products (e.g., ethanol,

meate. This process thus has as much in common with

volatile acids) from fermentation broths.

gas separation as it does pervaporation. In contrast with

pervaporation, however, uniformly high temperatures can

4. Production of Organic Acid Esters

be maintained throughout the membrane unit without in-

terstage reheating because the enthalpy of vaporization Fermentation-derivedorganicacidsandtheirestersarepo-

need not be supplied adiabatically from the feed stream. tentially important chemical feedstocks for polymers and

Since permeation flux varies directly with temperature, specialty polymers, but most significantly as alternative

operation under essentially isothermal conditions results solvents for industrial and consumer applications. For ex-

in a higher overall water removal rate. Consequently, ample, lactate esters are derived from renewable carbohy-

fewer stages are needed to reach a given ethanol purity. drate raw materials such as cornstarch. They exhibit much

Figure 25 shows the process flow diagram of a large vapor lower toxicity compared with halogenated hydrocarbons

permeation plant in operation, with a capacity of dehy- and ethylene glycol ethers and are environmentally be-

drating 30,000 L/day of 94% ethanol to 99.9%. nign. Some studies suggested that lactate ester solvents

have the potential of replacing petroleum-based solvents

3. Trace Organic Compound Removal from Water

In the United States the emission of volatile organic com-

pounds (VOCs) has been estimated to be as high as 5 mil-

lion metric tons annually. These pollutants are found

mostly in wastewater or contaminated groundwater. Per-

vaporation has been shown in various pilot-scale studies to

be well suited for purifying such wastewaters. A generic

design of such a system is shown in Fig. 26. Particularly

attractive are cases in which the value of the recovered

solvent is high (e.g., halogenated hydrocarbons or alkyl

esters) such that the payback period is relatively short,

or the hazard present by the compounds warrants even

costly remedial and restorative measures. Often, the most

cost-effective way of deploying pervaporation systems is

FIGURE 26 Removal of trace volatile organic compounds from

to combine it with a secondary method of clean up, such wastewater streams by pervaporation. (Membrane Technology

as activated carbon absorption. The pervaporation system and Research, Inc.)