Page 377 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 377

P1: GLQ Final Pages

Encyclopedia of Physical Science and Technology EN009K-419 July 19, 2001 20:57

312 Membranes, Synthetic, Applications

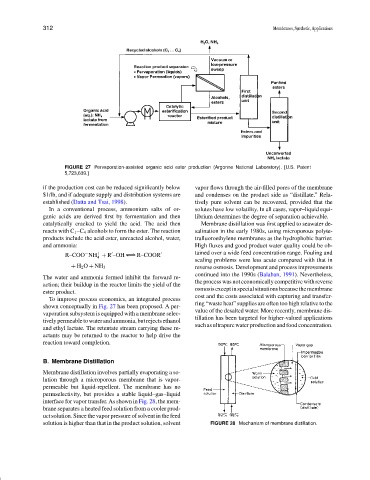

FIGURE 27 Pervaporation-assisted organic acid ester production (Argonne National Laboratory). [U.S. Patent

5,723,639.]

if the production cost can be reduced significantly below vapor flows through the air-filled pores of the membrane

$1/lb, and if adequate supply and distribution systems are and condenses on the product side as “distillate.” Rela-

established (Datta and Tsai, 1998). tively pure solvent can be recovered, provided that the

In a conventional process, ammonium salts of or- solutes have low volatility. In all cases, vapor–liquid equi-

ganic acids are derived first by fermentation and then librium determines the degree of separation achievable.

catalytically cracked to yield the acid. The acid then Membrane distillation was first applied to seawater de-

reacts with C 1 –C 4 alcohols to form the ester. The reaction salination in the early 1980s, using microporous polyte-

products include the acid ester, unreacted alcohol, water, trafluoroethylene membranes as the hydrophobic barrier.

and ammonia: High fluxes and good product water quality could be ob-

R–COO NH + R –OH − tained over a wide feed concentration range. Fouling and

+

− R–COOR

−

4

scaling problems were less acute compared with that in

+ H 2 O + NH 3 reverse osmosis. Development and process improvements

continued into the 1990s (Balaban, 1991). Nevertheless,

The water and ammonia formed inhibit the forward re-

the process was not economically competitive with reverse

action; their buildup in the reactor limits the yield of the

osmosisexceptinspecialsituationsbecausethemembrane

ester product.

cost and the costs associated with capturing and transfer-

To improve process economics, an integrated process

ring “waste heat” supplies are often too high relative to the

shown conceptually in Fig. 27 has been proposed. A per-

vaporation subsystem is equipped with a membrane selec- value of the desalted water. More recently, membrane dis-

tillation has been targeted for higher-valued applications

tivelypermeabletowaterandammonia,butrejectsethanol

suchasultrapurewaterproductionandfoodconcentration.

and ethyl lactate. The retentate stream carrying these re-

actants may be returned to the reactor to help drive the

reaction toward completion.

B. Membrane Distillation

Membrane distillation involves partially evaporating a so-

lution through a microporous membrane that is vapor-

permeable but liquid-repellent. The membrane has no

permselectivity, but provides a stable liquid–gas–liquid

interface for vapor transfer. As shown in Fig. 28, the mem-

brane separates a heated feed solution from a cooler prod-

uct solution. Since the vapor pressure of solvent in the feed

solution is higher than that in the product solution, solvent FIGURE 28 Mechanism of membrane distillation.