Page 372 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 372

P1: GLQ Final Pages

Encyclopedia of Physical Science and Technology EN009K-419 July 19, 2001 20:57

Membranes, Synthetic, Applications 307

4. Water Vapor Separation amount of air also leaks through the pores and carries

the water vapor away from the membrane. In this way,

Increasing environmental awareness and rising costs of

the accumulated water vapor in the membrane sublayer is

energy and chemical supplies have helped spur interest

continually swept away, thereby preventing condensation

in membrane processes as a means of recovering those

and loss of water removal capability. Micropores normally

resources. Although vapor separation is closely related

considered defects in the membrane are in fact a necessary

to gas permeation in mechanism, the presence of con-

feature in this membrane design. Very low dew points can

densable components permits unique process designs and

be reached with this membrane unit with no additional

opportunities for energy recovery.

power input and no moving parts. The inherent reliability

Water vapor separation from air is an example where

and simplicity of this product makes it attractive for instru-

significant energy recovery is possible. Many industries,

mentation applications and at locations that are difficult

including pulp-and-paper, textile, and food processing,

to access.

use large amounts of energy to dry their products. The

water vapor in the exhaust air from the dryer carries with

it the latent heat of vaporization. Reclaiming this latent 5. Organic Vapor Separations

heat could substantially reduce the net thermal energy re-

Organic vapor separation from air is a means of controlling

quirement of the drying process. Heat exchange between

pollutionandrecoveringvaluableresources.Anindication

incoming and exhaust streams is inefficient because only

of the environmental problem is the more than 30 mil-

sensible heat is recovered, and because the temperature

lion tons per year of volatile organics emitted in 1975

differential is usually small. Condensing the water vapor

from all stationary sources in the United States. These

by recompressing the moist exhaust air would release the

included petroleum refineries, chemical plants, and de-

latent heat, but this approach is also inefficient because

fective solvent storage and conveyance facilities. Much of

most of the energy is expended in compressing the major

the vapors emitted—hydrocarbons, chlorinated solvents,

component—air. A membrane-aided vapor-compression

alcohols, and ketones—are potentially recoverable with

process shown in Fig. 19 could be a more efficient alterna-

membranes highly permeable to organics and relatively

tive. Moisture from the dryer exhaust would pass through a

impermeable to air. A scheme for treating a solvent-laden

hydrophilic membrane and be compressed. The latent heat

air stream from a drying oven is shown in Fig. 20, where

liberated can be used to preheat the feed air for the dryer. It

liquid solvent is recovered by compressing the permeate

has been estimated that more than half of the energy used

stream, and hot air is recycled to the drying oven.

in a paper drying machine can be reclaimed in this way.

In gas- or vapor-phase chemical reactors, the product

Economic feasibility of this scheme hinges on the relative

stream typically contains some residual reactants and one

costs of energy and that of the membrane system.

or more inert gases. At the end of the reaction cycle the

Already commercialized is an innovative membrane

product is recovered—for example, by condensation—

module capable of in-line drying of air. Moist air is fed

and the remaining gases are vented to the atmosphere or

to one side of an inherently water-permeable membrane,

flared. Significant quantities of reactants can be lost in this

which has a low density of surface pores. While water va-

way, some adding to the environmental burden of the pro-

por diffuses through the membrane preferentially, a small

cess. Membrane systems have been designed to address

both issues. By selecting a membrane more permeable to

the reactant than to the inert gases, a highly concentrated

reactant stream can be collected as permeate and recycled

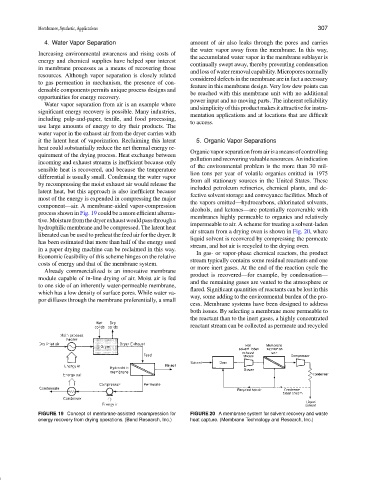

FIGURE 19 Concept of membrane-assisted recompression for FIGURE 20 A membrane system for solvent recovery and waste

energy recovery from drying operations. (Bend Research, Inc.) heat capture. (Membrane Technology and Research, Inc.)