Page 371 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 371

P1: GLQ Final Pages

Encyclopedia of Physical Science and Technology EN009K-419 July 19, 2001 20:57

306 Membranes, Synthetic, Applications

compound that preferentially and reversibly complexes creases the concentration of carbon dioxide in the natural

with oxygen. By exposing this liquid membrane (q.v.) to gas produced and thus reduces its energy value. More-

air on one side and a vacuum on the other side, the carriers over, the cost of EOR would be prohibitively high un-

capture oxygen from the air and release it on the evacu- less the carbon dioxide is reused. Membranes have been

ated side. The result is substantial enrichment of oxygen. used successfully at production wells to separate the car-

However, many technical problems remain regarding the bon dioxide for reinjection while delivering a purified

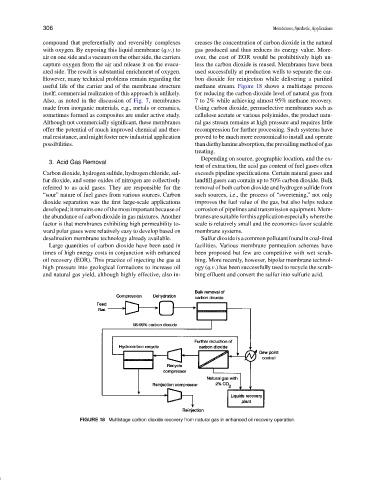

useful life of the carrier and of the membrane structure methane stream. Figure 18 shows a multistage process

itself; commercial realization of this approach is unlikely. for reducing the carbon dioxide level of natural gas from

Also, as noted in the discussion of Fig. 7, membranes 7 to 2% while achieving almost 95% methane recovery.

made from inorganic materials, e.g., metals or ceramics, Using carbon dioxide, permselective membranes such as

sometimes formed as composites are under active study. cellulose acetate or various polyimides, the product natu-

Although not commercially significant, these membranes ral gas stream remains at high pressure and requires little

offer the potential of much improved chemical and ther- recompression for further processing. Such systems have

mal resistance, and might foster new industrial application proved to be much more economical to install and operate

possibilities. thandiethylamineabsorption,theprevailingmethodofgas

treating.

Depending on source, geographic location, and the ex-

3. Acid Gas Removal

tent of extraction, the acid gas content of fuel gases often

Carbon dioxide, hydrogen sulfide, hydrogen chloride, sul- exceeds pipeline specifications. Certain natural gases and

fur dioxide, and some oxides of nitrogen are collectively landfill gases can contain up to 50% carbon dioxide. Bulk

referred to as acid gases. They are responsible for the removal of both carbon dioxide and hydrogen sulfide from

“sour” nature of fuel gases from various sources. Carbon such sources, i.e., the process of “sweetening,” not only

dioxide separation was the first large-scale applications improves the fuel value of the gas, but also helps reduce

developed; it remains one of the most important because of corrosion of pipelines and transmission equipment. Mem-

the abundance of carbon dioxide in gas mixtures. Another branesaresuitableforthisapplicationespeciallywherethe

factor is that membranes exhibiting high permeability to- scale is relatively small and the economics favor scalable

ward polar gases were relatively easy to develop based on membrane systems.

desalination membrane technology already available. Sulfurdioxideisacommonpollutantfoundincoal-fired

Large quantities of carbon dioxide have been used in facilities. Various membrane permeation schemes have

times of high energy costs in conjunction with enhanced been proposed but few are competitive with wet scrub-

oil recovery (EOR). This practice of injecting the gas at bing. More recently, however, bipolar membrane technol-

high pressure into geological formations to increase oil ogy (q.v.) has been successfully used to recycle the scrub-

and natural gas yield, although highly effective, also in- bing effluent and convert the sulfur into sulfuric acid.

FIGURE 18 Multistage carbon dioxide recovery from natural gas in enhanced oil recovery operation.