Page 192 - Academic Press Encyclopedia of Physical Science and Technology 3rd Polymer

P. 192

P1: GLM Final Pages

Encyclopedia of Physical Science and Technology EN012c-598 July 26, 2001 15:59

Polymers, Mechanical Behavior 701

of convenience, it is common for results to be reported

utilizing the engineering stress in contrast to true stress,

thereby underestimating the actual stress at the time of

failure for materials that show significant deformation.

For specimens that undergo low deformation before

fracture (e.g., glassy polystyrene), the difference between

these two stress parameters is not great and of course

becomes zero in the limit of no deformation. An important

point here is related to the presentation of results; it

would be misleading to report stress arbitrarily without

specifying whether it is engineering stress or true stress.

As will be discussed later, one may often be able to relate

σ t to σ 0 for homogeneous constant volume deformations.

In the case of shear deformation, if simple shear is

imposed, there is no change in the cross-sectional area

and hence only a single stress value must be reported.

This is conventionally denoted by τ (a shear stress) in

contrast to σ (a tensile stress).

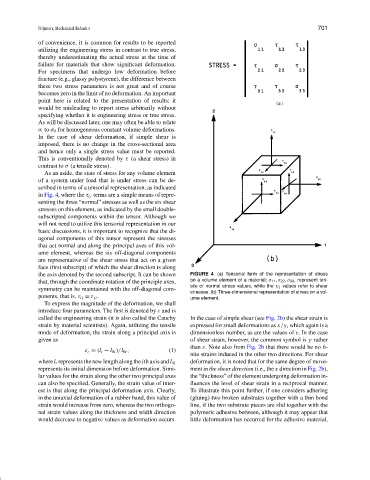

As an aside, the state of stress for any volume element

of a system under load that is under stress can be de-

scribed in terms of a tensorial representation, as indicated

in Fig. 4, where the τ ij terms are a simple means of repre-

senting the three “normal” stresses as well as the six shear

stresses on this element, as indicated by the small double-

subscripted components within the tensor. Although we

will not need to utilize this tensorial representation in our

basic discussions, it is important to recognize that the di-

agonal components of this tensor represent the stresses

that act normal and along the principal axes of this vol-

ume element, whereas the six off-diagonal components

are representative of the shear stress that act on a given

face (first subscript) of which the shear direction is along

the axis denoted by the second subscript. It can be shown FIGURE 4 (a) Tensorial form of the representation of stress

that, through the coordinate rotation of the principle axes, on a volume element of a material; σ 11 , σ 22 , σ 33 , represent ten-

sile or normal stress values, while the τ ij values refer to shear

symmetry can be maintained with the off-diagonal com-

stresses. (b) Three-dimensional representation of stress on a vol-

ponents, that is, τ ij = τ ji . ume element.

To express the magnitude of the deformation, we shall

introduce four parameters. The first is denoted by ε and is

called the engineering strain (it is also called the Cauchy In the case of simple shear (see Fig. 2b) the shear strain is

strain by material scientists). Again, utilizing the tensile expressed for small deformations as x /y, which again is a

mode of deformation, the strain along a principal axis is dimensionless number, as are the values of ε. In the case

given as of shear strain, however, the common symbol is γ rather

than ε. Note also from Fig. 2b that there would be no fi-

ε i = (l i − l 0i )/l 0i , (1)

nite strains induced in the other two directions. For shear

wherel i represents the new length along the ith axis andl 0i deformation, it is noted that for the same degree of move-

represents its initial dimension before deformation. Simi- ment in the shear direction (i.e., the x direction in Fig. 2b),

lar values for the strain along the other two principal axes the “thickness” of the element undergoing deformation in-

can also be specified. Generally, the strain value of inter- fluences the level of shear strain in a reciprocal manner.

est is that along the principal deformation axis. Clearly, To illustrate this point further, if one considers adhering

in the uniaxial deformation of a rubber band, this value of (gluing) two broken substrates together with a thin bond

strain would increase from zero, whereas the two orthogo- line, if the two substrate pieces are slid together with the

nal strain values along the thickness and width direction polymeric adhesive between, although it may appear that

would decrease to negative values as deformation occurs. little deformation has occurred for the adhesive material,