Page 184 - Energy from Toxic Organic Waste for Heat and Power Generation

P. 184

164 Energy from Toxic Organic Waste for Heat and Power Generation

Table 11.1 Physical characterization of oil

Temp (°C) Carbon range Fraction

Upto 130 C 6 –C 10 Gasoline

130–170 C 6 –C 10 Naphtha

170–230 C 11 –C 12 Kerosene (paraffin) oil

230–320 C 13 –C 17 Light gas oil (high-speed diesel component)

320–380 C 18 –C 25 Heavy gas oil (high-speed diesel component)

>380 >C 25 Reduced crude oil

11.4 DOWN DRAFT GASIFIER FOR PRODUCTION OF

PRODUCER GAS

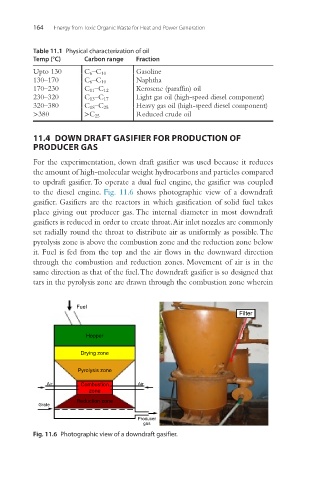

For the experimentation, down draft gasifier was used because it reduces

the amount of high-molecular weight hydrocarbons and particles compared

to updraft gasifier. To operate a dual fuel engine, the gasifier was coupled

to the diesel engine. Fig. 11.6 shows photographic view of a downdraft

gasifier. Gasifiers are the reactors in which gasification of solid fuel takes

place giving out producer gas. The internal diameter in most downdraft

gasifiers is reduced in order to create throat. Air inlet nozzles are commonly

set radially round the throat to distribute air as uniformly as possible. The

pyrolysis zone is above the combustion zone and the reduction zone below

it. Fuel is fed from the top and the air flows in the downward direction

through the combustion and reduction zones. Movement of air is in the

same direction as that of the fuel. The downdraft gasifier is so designed that

tars in the pyrolysis zone are drawn through the combustion zone wherein

Fuel

Filter

Hopper

Drying zone

Pyrolysis zone

Air Combustion Air

zone

Reduction zone

Grate

Producer

gas

Fig. 11.6 Photographic view of a downdraft gasifier.