Page 185 - Energy from Toxic Organic Waste for Heat and Power Generation

P. 185

Power Generation From Renewable Energy Sources 165

Checking quality of producer

Producer gas flow line

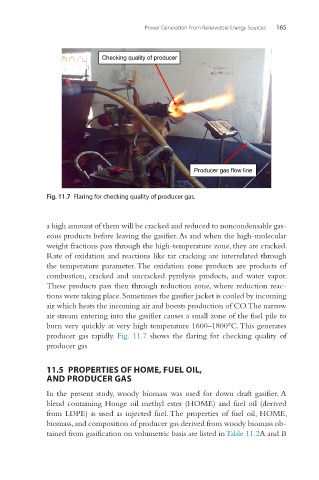

Fig. 11.7 Flaring for checking quality of producer gas.

a high amount of them will be cracked and reduced to noncondensable gas-

eous products before leaving the gasifier. As and when the high-molecular

weight fractions pass through the high-temperature zone, they are cracked.

Rate of oxidation and reactions like tar cracking are interrelated through

the temperature parameter. The oxidation zone products are products of

combustion, cracked and uncracked pyrolysis products, and water vapor.

These products pass then through reduction zone, where reduction reac-

tions were taking place. Sometimes the gasifier jacket is cooled by incoming

air which heats the incoming air and boosts production of CO. The narrow

air stream entering into the gasifier causes a small zone of the fuel pile to

burn very quickly at very high temperature 1600–1800°C. This generates

producer gas rapidly. Fig. 11.7 shows the flaring for checking quality of

producer gas

11.5 PROPERTIES OF HOME, FUEL OIL,

AND PRODUCER GAS

In the present study, woody biomass was used for down draft gasifier. A

blend containing Honge oil methyl ester (HOME) and fuel oil (derived

from LDPE) is used as injected fuel. The properties of fuel oil, HOME,

biomass, and composition of producer gas derived from woody biomass ob-

tained from gasification on volumetric basis are listed in Table 11.2A and B