Page 38 - Energy from Toxic Organic Waste for Heat and Power Generation

P. 38

26 Energy from Toxic Organic Waste for Heat and Power Generation

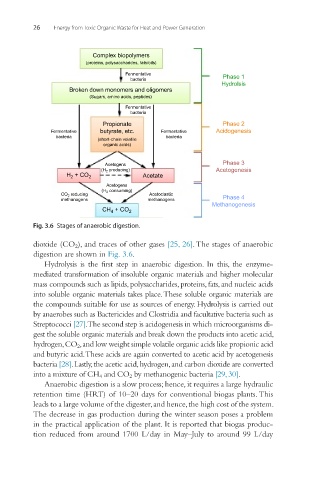

Complex biopolymers

(proteins, polysaccharides, fats/oils)

Fermentative

bacteria Phase 1

Hydrolsis

Broken down monomers and oligomers

(Sugars, amino acids, peptides)

Fermentative

bacteria

Propionate Phase 2

Fermentative butyrate, etc. Fermentative Acidogenesis

bacteria bacteria

(short-chain volatile

organic acids)

Acetogens Phase 3

(H 2 producing) Acetogenesis

H 2 + CO 2 Acetate

Acetogens

(H 2 consuming)

CO 2 reducing Acetoclastic

methanogens methanogens Phase 4

Methanogenesis

CH + CO 2

4

Fig. 3.6 Stages of anaerobic digestion.

dioxide (CO 2 ), and traces of other gases [25, 26]. The stages of anaerobic

digestion are shown in Fig. 3.6.

Hydrolysis is the first step in anaerobic digestion. In this, the enzyme-

mediated transformation of insoluble organic materials and higher molecular

mass compounds such as lipids, polysaccharides, proteins, fats, and nucleic acids

into soluble organic materials takes place. These soluble organic materials are

the compounds suitable for use as sources of energy. Hydrolysis is carried out

by anaerobes such as Bactericides and Clostridia and facultative bacteria such as

Streptococci [27]. The second step is acidogenesis in which microorganisms di-

gest the soluble organic materials and break down the products into acetic acid,

hydrogen, CO 2 , and low weight simple volatile organic acids like propionic acid

and butyric acid. These acids are again converted to acetic acid by acetogenesis

bacteria [28]. Lastly, the acetic acid, hydrogen, and carbon dioxide are converted

into a mixture of CH 4 and CO 2 by methanogenic bacteria [29, 30].

Anaerobic digestion is a slow process; hence, it requires a large hydraulic

retention time (HRT) of 10–20 days for conventional biogas plants. This

leads to a large volume of the digester, and hence, the high cost of the system.

The decrease in gas production during the winter season poses a problem

in the practical application of the plant. It is reported that biogas produc-

tion reduced from around 1700 L/day in May–July to around 99 L/day