Page 280 - Engineered Interfaces in Fiber Reinforced Composites

P. 280

Chapter 6. Interface mechanics and fracture toughness theories 26 1

Based on a shear-lag model, Nairn (1990) has also derived an expression for the

energy release rates due to the two opposing fracture modes in unidirectional fiber

composites. The material heterogeneity, material anisotropy and finite width effects

have been considered. The fracture mechanics criterion requires that the strain

energy release rate ratio, GL/@, is equal to or greater than the toughness ratio for

longitudinal splitting

(6.22)

where GL is the strain energy release rate for longitudinal splitting parallel to the

fiber, whether failure occurs due to debonding at the fiber-matrix interface, shear

failure of matrix materials or combination of these two. GT is the strain energy

release rate for transverse fracture of the fiber or composite by a self-similar crack.

GLT and EL are the effective in-plane shear modulus and Young's modulus of the

unidirectional fiber composite, respectively. It follows that depending on the type of

longitudinal splitting, the critical RL should be related to the matrix shear fracture

toughness in mode 11, or to the fiber-matrix interface fracture toughness, R;.

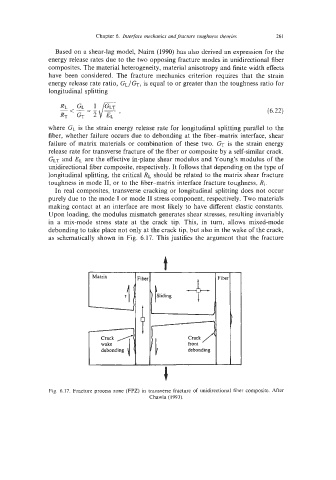

In real composites, transverse cracking or longitudinal splitting does not occur

purely due to the mode I or mode I1 stress component, respectively. Two materials

making contact at an interface are most likely to have different elastic constants.

Upon loading, the modulus mismatch generates shear stresses, resulting invariably

in a mix-mode stress state at the crack tip. This, in turn, allows mixed-mode

debonding to take place not only at the crack tip, but also in the wake of the crack,

as schematically shown in Fig. 6.17. This justifies the argument that the fracture

rk debonding I I

debonding

I ' I I

Fig. 6.17. Fracture process zone (FPZ) in transverse fracture of unidirectional fiber composite. After

Chawla (1993).