Page 54 - Engineered Interfaces in Fiber Reinforced Composites

P. 54

Chapter 2. Characterization of interfaces 37

K = dl - (!y (2.21)

= sin-ld- n2 - 1 .

(2.22)

n2 - a2

F(4, K) and E($, K) are elliptical integrals of the first and second kind, respectively.

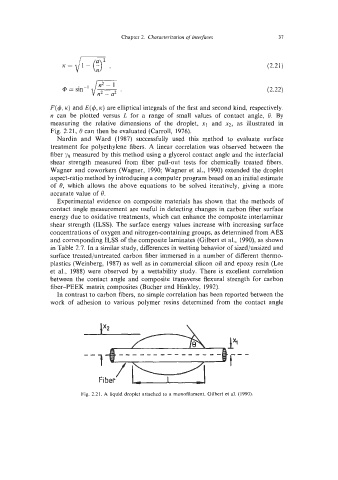

n can be plotted versus L for a range of small values of contact angle, 8. By

measuring the relative dimensions of the droplet, XI and x2, as illustrated in

Fig. 2.21, 8 can then be evaluated (Carroll, 1976).

Nardin and Ward (1987) successfully used this method to evaluate surface

treatment for polyethylene fibers. A linear correlation was observed between the

fiber ys measured by this method using a glycerol contact angle and the interfacial

shear strength measured from fiber pull-out tests for chemically treated fibers.

Wagner and coworkers (Wagner, 1990; Wagner et al., 1990) extended the droplet

aspect-ratio method by introducing a computer program based on an initial estimate

of 8, which allows the above equations to be solved iteratively, giving a more

accurate value of 8.

Experimental evidence on composite materials has shown that the methods of

contact angle measurement are useful in detecting changes in carbon fiber surface

energy due to oxidative treatments, which can enhance the composite interlaminar

shear strength (ILSS). The surface energy values increase with increasing surface

concentrations of oxygen and nitrogen-containing groups, as determined from AES

and corresponding ILSS of the composite laminates (Gilbert et al., 1990), as shown

in Table 2.7. In a similar study, differences in wetting behavior of sized/unsized and

surface treated/untreated carbon fiber immersed in a number of different thermo-

plastics (Weinberg, 1987) as well as in commercial silicon oil and epoxy resin (Lee

et al., 1988) were observed by a wettability study. There is excellent correlation

between the contact angle and composite transverse flexural strength for carbon

fiber-PEEK matrix composites (Bucher and Hinkley, 1992).

In contrast to carbon fibers, no simple correlation has been reported between the

work of adhesion to various polymer resins determined from the contact angle

-

Fiber' 'I

Fig. 2.21. A liquid droplet attachcd to a monofilament. Gilbert et al. (1990).