Page 77 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 77

Engineering Design with SOLIDWORKS® 2018 Fundamentals of Part Modeling

The engineering group calculates working

~ ~~ $~ > ~r~·~r$r~, >

loads on test samples. Material test samples v v

include Plain Carbon Steel, AISI 304 steel ~ ROD (Default< <Default> _Displ ~ GUIDE (Default < <Default> _Dis

and a machinable plastic Nylon 101. ~ I History [€> I History

~ Sensors ~ Sensors

The engineering group recommends AISI

• 1/l I Annotations ~ [A I Annotations

304 steel for the ROD and GUIDE parts. [fl Equations ~ Equations

o- o-

~:a Plain Carbon Steel ~:,c; AISI 304

In the real world, there are numerous time

[!] Front Plane [!] Front Plane

constraints. The customer requires a quote, [!] Top Plane [!] Top Plane

design sketches and a delivery schedule, [!] Right Plane [!] Right Plane

YESTERDAY. If you wait for all of the L Origin L Origin

required design information, you will miss • ~ Base Extrude • ~ Base Extrude

• ~ Front Cut ~ ~ Slot Cut

the project deadline.

• ~ Front Hole Caliil M irror1

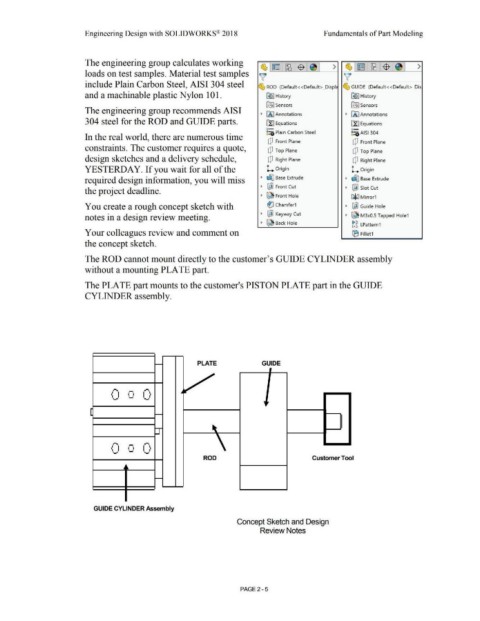

You create a rough concept sketch with i:l'.J Chamfer1 • ~ Guide Hole

notes in a design review meeting. • ~ Keyway Cut ~ ~ M3x0.5 Tapped Hole1

• ~ Back Hole gg LPattern1

Your colleagues review and comment on (B Fillet 1

the concept sketch.

The ROD cannot mount directly to the customer's GUIDE CYLINDER assembly

without a mounting PLATE part.

The PLATE part mounts to the customer's PISTON PLATE part in the GUIDE

CYLINDER assembly.

PLATE GUIDE

0 0 0

-

0 0 0

ROD Customer Too I

GUIDE CYLINDER Assembly

Concept Sketch and Design

Review Notes

PAGE2 - 5