Page 65 - Environmental Nanotechnology Applications and Impacts of Nanomaterials

P. 65

Nanomaterials Fabrication 51

a 001 b

001

001

101 101 001

101

101

c

001

001

101

101

101 101

d

001

001 101 001

101

011 011

Seed

e

001

001

101

101

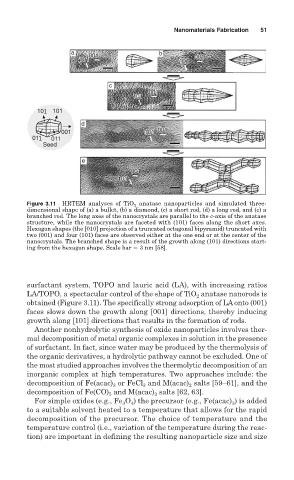

Figure 3.11 HRTEM analyses of TiO 2 anatase nanoparticles and simulated three-

dimensional shape of (a) a bullet, (b) a diamond, (c) a short rod, (d) a long rod, and (e) a

branched rod. The long axes of the nanocrystals are parallel to the c-axis of the anatase

structure, while the nanocrystals are faceted with (101) faces along the short axes.

Hexagon shapes (the [010] projection of a truncated octagonal bipyramid) truncated with

two (001) and four (101) faces are observed either at the one end or at the center of the

nanocrystals. The branched shape is a result of the growth along (101) directions start-

ing from the hexagon shape. Scale bar 3 nm [58].

surfactant system, TOPO and lauric acid (LA), with increasing ratios

LA/TOPO, a spectacular control of the shape of TiO anatase nanorods is

2

obtained (Figure 3.11). The specifically strong adsorption of LAonto (001)

faces slows down the growth along [001] directions, thereby inducing

growth along [101] directions that results in the formation of rods.

Another nonhydrolytic synthesis of oxide nanoparticles involves ther-

mal decomposition of metal organic complexes in solution in the presence

of surfactant. In fact, since water may be produced by the thermolysis of

the organic derivatives, a hydrolytic pathway cannot be excluded. One of

the most studied approaches involves the thermolytic decomposition of an

inorganic complex at high temperatures. Two approaches include: the

decomposition of Fe(acac) or FeCl and M(acac) salts [59–61], and the

3

3

2

decomposition of Fe(CO) and M(acac) salts [62, 63].

2

5

For simple oxides (e.g., Fe O ) the precursor (e.g., Fe(acac) ) is added

3

4

3

to a suitable solvent heated to a temperature that allows for the rapid

decomposition of the precursor. The choice of temperature and the

temperature control (i.e., variation of the temperature during the reac-

tion) are important in defining the resulting nanoparticle size and size