Page 66 - Environmental Nanotechnology Applications and Impacts of Nanomaterials

P. 66

52 Principles and Methods

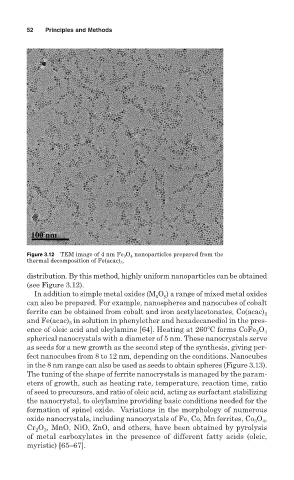

Figure 3.12 TEM image of 4 nm Fe 3 O 4 nanoparticles prepared from the

thermal decomposition of Fe(acac) 3 .

distribution. By this method, highly uniform nanoparticles can be obtained

(see Figure 3.12).

In addition to simple metal oxides (M x O y ) a range of mixed metal oxides

can also be prepared. For example, nanospheres and nanocubes of cobalt

ferrite can be obtained from cobalt and iron acetylacetonates, Co(acac) 2

and Fe(acac) 3 in solution in phenylether and hexadecanediol in the pres-

ence of oleic acid and oleylamine [64]. Heating at 260 C forms CoFe 2 O 4

spherical nanocrystals with a diameter of 5 nm. These nanocrystals serve

as seeds for a new growth as the second step of the synthesis, giving per-

fect nanocubes from 8 to 12 nm, depending on the conditions. Nanocubes

in the 8 nm range can also be used as seeds to obtain spheres (Figure 3.13).

The tuning of the shape of ferrite nanocrystals is managed by the param-

eters of growth, such as heating rate, temperature, reaction time, ratio

of seed to precursors, and ratio of oleic acid, acting as surfactant stabilizing

the nanocrystal, to oleylamine providing basic conditions needed for the

formation of spinel oxide. Variations in the morphology of numerous

oxide nanocrystals, including nanocrystals of Fe, Co, Mn ferrites, Co 3 O 4 ,

Cr 2 O 3 , MnO, NiO, ZnO, and others, have been obtained by pyrolysis

of metal carboxylates in the presence of different fatty acids (oleic,

myristic) [65–67].