Page 157 - Failure Analysis Case Studies II

P. 157

142

the grains and at grain boundaries (Fig. 4). Hairline cracks were clearly visible along some of the

grain boundaries.

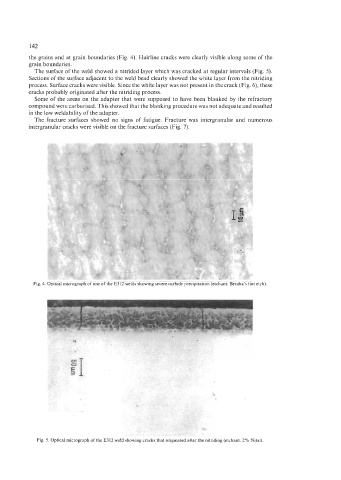

The surface of the weld showed a nitrided layer which was cracked at regular intervals (Fig. 5).

Sections of the surface adjacent to the weld bead clearly showed the white layer from the nitriding

process. Surface cracks were visible. Since the white layer was not present in the crack (Fig. 6), these

cracks probably originated after the nitriding process.

Some of the areas on the adapter that were supposed to have been blanked by the refractory

compound were carburised. This showed that the blanking procedure was not adequate and resulted

in the low weldability of the adapter.

The fracture surfaces showed no signs of fatigue. Fracture was intergranular and numerous

intergranular cracks were visible on the fracture surfaces (Fig. 7).

Fig. 4. Optical micrograph of one of the E312 welds showing severe carbide precipitation (etchant: Beraha's tint etch).

Fig. 5. Optical micrograph of the E312 weld showing cracks that originated after the nitriding (etchant: 2% Nital)