Page 185 - Failure Analysis Case Studies II

P. 185

170

2. Survey of failed whole radiator

The failed part was examined for its surface quality first, and key features then examined with

an optical microscope. SEM was used to resolve details of interest.

2.1. Macroscopic inspection

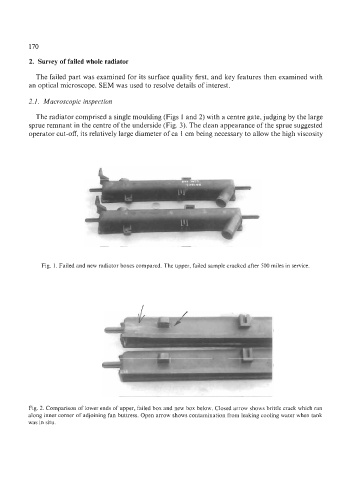

The radiator comprised a single moulding (Figs 1 and 2) with a centre gate, judging by the large

sprue remnant in the centre of the underside (Fig. 3). The clean appearance of the sprue suggested

operator cut-off, its relatively large diameter of ca 1 cm being necessary to allow the high viscosity

Fig. 1. Failed and new radiator boxes compared. The upper, failed sample cracked after 500 miles in service.

Fig. 2. Comparison of lower ends of upper, failed box and new box below. Closed arrow shows brittle crack which ran

along inner corner of adjoining fan buttress. Open arrow shows contamination from leaking cooling water when tank

was in situ.