Page 82 - Fiber Bragg Gratings

P. 82

3.1 Methods for fiber Bragg grating fabrication 61

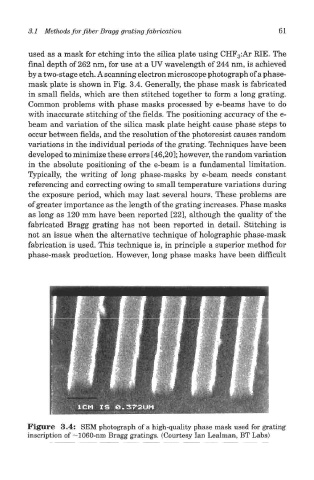

used as a mask for etching into the silica plate using CHF 3:Ar RIE. The

final depth of 262 nm, for use at a UV wavelength of 244 nm, is achieved

by a two-stage etch. A scanning electron microscope photograph of a phase-

mask plate is shown in Fig. 3.4. Generally, the phase mask is fabricated

in small fields, which are then stitched together to form a long grating.

Common problems with phase masks processed by e-beams have to do

with inaccurate stitching of the fields. The positioning accuracy of the e-

beam and variation of the silica mask plate height cause phase steps to

occur between fields, and the resolution of the photoresist causes random

variations in the individual periods of the grating. Techniques have been

developed to minimize these errors [46,20]; however, the random variation

in the absolute positioning of the e-beam is a fundamental limitation.

Typically, the writing of long phase-masks by e-beam needs constant

referencing and correcting owing to small temperature variations during

the exposure period, which may last several hours. These problems are

of greater importance as the length of the grating increases. Phase masks

as long as 120 mm have been reported [221, although the quality of the

fabricated Bragg grating has not been reported in detail. Stitching is

not an issue when the alternative technique of holographic phase-mask

fabrication is used. This technique is, in principle a superior method for

phase-mask production. However, long phase masks have been difficult

Figure 3.4: SEM photograph of a high-quality phase mask used for grating

inscription of ~1060-nm Bragg gratings. (Courtesy Ian Lealman, BT Labs)