Page 233 - Fiber Fracture

P. 233

218 H.U. Kunzi

500

400

m

2 100

bamboo structure

0 1 1 Number of cycles to rupture - 1

o6

os

o2

1

1

04

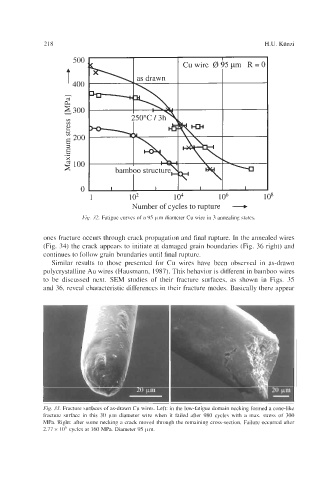

Fig. 32. Fatigue curves of a 95 bm diameter Cu wire in 3 annealing states

ones fracture occurs through crack propagation and final rupture. In the annealed wires

(Fig. 34) the crack appears to initiate at damaged grain boundaries (Fig. 36 right) and

continues to follow grain boundaries until final rupture.

Similar results to those presented for Cu wires have been observed in as-drawn

polycrystalline Au wires (Hausmann, 1987). This behavior is different in bamboo wires

to be discussed next. SEM studies of their fracture surfaces, as shown in Figs. 35

and 36, reveal characteristic differences in their fracture modes. Basically there appear

Fig. 33. Fracture surfaces of as-drawn Cu wires. Left: in the low-fatigue domain necking formed a cone-like

fracture surface in this 30 bm diameter wire when it failed after 980 cycles with a max. stress of 300

MPa. Right: after some necking a crack moved through the remaining cross-section. Failure occurred after

2.77 x 10' cycles at 160 MPa. Diameter 95 bm.