Page 236 - Fiber Fracture

P. 236

STRENGTH AND FRACTURE OF METALLIC FILAMENTS 22 1

t 2oo

E

2 20

.e

x

5

0

Number of cycles to rupture +

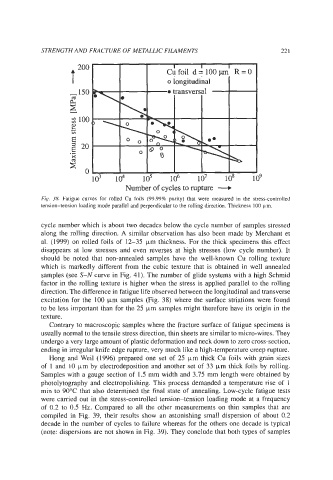

Fig. 38. Fatigue curves for rolled Cu foils (99.99% punty) that were measured in the stress-controlled

tension-tension loading mode parallel and perpendicular to the rolling direction. Thickness Io0 pm.

cycle number which is about two decadcs below the cycle number of samples stressed

along the rolling direction. A similar observation has also been made by Merchant et

al. (1999) on rolled foils of 12-35 pm thickness. For the thick specimens this effect

disappears at low stresses and even reverses at high stresses (low cycle number). It

should be noted that non-annealed samples have the well-known Cu rolling texture

which is markedly different from the cubic texture that is obtained in well annealed

samples (see S-N curve in Fig. 41). The number of glide systems with a high Schmid

factor in the rolling texture is higher when the stress is applied parallel to the rolling

direction. The difference in fatigue life observed between the longitudinal and transverse

excitation for the 100 pm samples (Fig. 38) where the surface striations were found

to be less important than for the 25 pm samples might therefore have its origin in the

texture.

Contrary to macroscopic samples where the fracture surface of fatigue specimens is

usually normal to the tensile stress direction, thin sheets are similar to micro-wires. They

undergo a very large amount of plastic deformation and neck down to zero cross-section,

ending in irregular knife edge rupture, very much like a high-temperature creep rupture.

Hong and Weil (1996) prepared one set of 25 pm thick Cu foils with grain sizes

of 1 and 10 pm by electrodeposition and another set of 33 pm thick foils by rolling.

Samples with a gauge section of 1.5 mm width and 3.75 mm length were obtained by

photolytography and electropolishing. This process demanded a temperature rise of 1

min to 90°C that also determined the final state of annealing. Low-cycle fatigue tests

were carried out in the stress-controlled tension-tension loading mode at a frequency

of 0.2 to 0.5 Hz. Compared to all the other measurements on thin samples that are

compiled in Fig. 39, their results show an astonishing small dispersion of about 0.2

decade in the number of cycles to failure whereas for the others one decade is typical

(note: dispersions are not shown in Fig. 39). They conclude that both types of samples