Page 239 - Fiber Fracture

P. 239

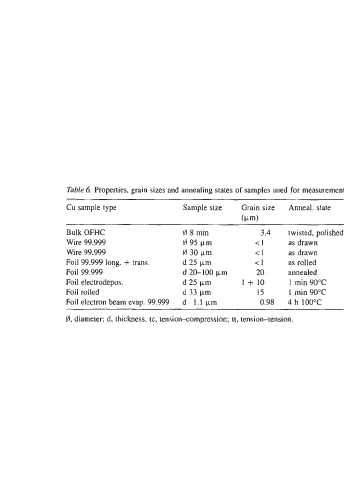

Table 6. Properties, grain sizes and annealing states of samples used for measurements represented in Fig. 39

Cu sample type Sample size Grain size Anneal. state Mode and freq. R0.2 R,,, Ref.

(Pm) (Hz) (MPa) (MPa)

Bulk OFHC G18mm 3.4 twisted, polished tc, 30 79 238 Thompson and Backofen ( I97 I )

Wire 99.999 v) 95 pm <I as drawn tt, 30 437 475 Hausmann (1987)

Wire 99.999 v) 30 pm <1 as drawn tt, 30 487 514 Hausmann (1987)

Foil 99.999 long. + trans. d 25 km <I as rolled tt, 700 - - Judelewicz (1 993)

Foil 99.999 d 20-100 km 20 annealed tt. 700 - - Judelewicz (1993)

Foil electrodepos. d 25 Krn I + 10 1 min 9OoC tt, 0.2-0.5 - 439 Hong and Weil (1996)

Foil rolled d 33 km 15 1 min 9OoC tt, 0.2-0.5 - 309 Hong and Weil(l996)

Foil electron beam evap. 99.999 d 1.1 km 0.98 4h 100°C tt, 0.066 330 339 Read (1998a)

61, diameter; d, thickness. tc, tensionxompression; tt, tension-tension.