Page 243 - Fiber Fracture

P. 243

STRENGTH AND FRACTURE OF METALLIC FILAMENTS 227

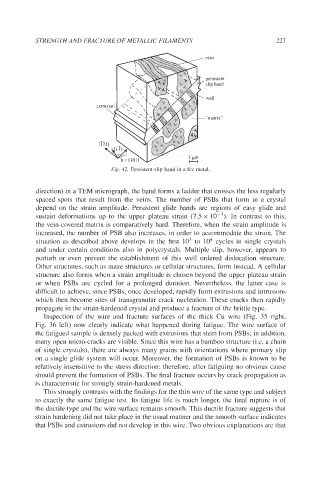

Fig. 42. Persistent slip band in a fcc metal.

direction) in a TEM micrograph, the band forms a ladder that crosses the less regularly

spaced spots that result from the veins. The number of PSBs that form in a crystal

depend on the strain amplitude. Persistent glide bands are regions of easy glide and

sustain deformations up to the upper plateau strain (7.5 x In contrast to this,

the vein-covered matrix is comparatively hard. Therefore, when the strain amplitude is

increased, the number of PSB also increases, in order to accommodate the strain. The

situation as described above develops in the first lo3 to lo4 cycles in single crystals

and under certain conditions also in polycrystals. Multiple slip, however, appears to

perturb or even prevent the establishment of this well ordered dislocation structure.

Other structures, such as maze structures or cellular structures, form instead. A cellular

structure also forms when a strain amplitude is chosen beyond the upper plateau strain

or when PSBs are cycled for a prolonged duration. Nevertheless, the latter case is

difficult to achieve, since PSBs, once developed, rapidly form extrusions and intrusions

which then become sites of transgranular crack nucleation. These cracks then rapidly

propagate in the strain-hardened crystal and produce a fracture of the brittle type.

Inspection of the wire and fracture surfaces of the thick Cu wire (Fig. 35 right,

Fig. 36 left) now clearly indicate what happened during fatigue. The wire surface of

the fatigued sample is densely packed with extrusions that stem from PSBs; in addition,

many open micro-cracks are visible. Since this wire has a bamboo structure (i.e. a chain

of single crystals), there are always many grains with orientations where primary slip

on a single glide system will occur. Moreover, the formation of PSBs is known to be

relatively insensitive to the stress direction; therefore, after fatiguing no obvious cause

should prevent the formation of PSBs. The final fracture occurs by crack propagation as

is characteristic for strongly strain-hardened metals.

This strongly contrasts with the findings for the thin wire of the same type and subject

to exactly the same fatigue test. Its fatigue life is much longer, the final rupture is of

the ductile type and the wire surface remains smooth. This ductile fracture suggests that

strain hardening did not take place in the usual manner and the smooth surface indicates

that PSBs and extrusions did not develop in this wire. Two obvious explanations are that