Page 253 - Fiber Fracture

P. 253

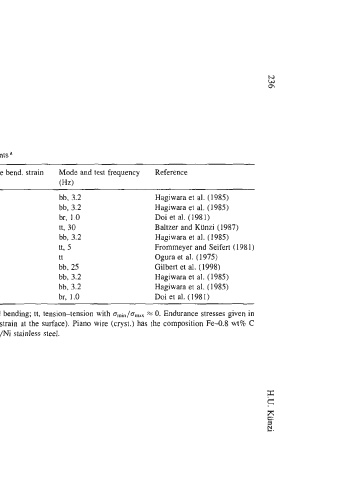

Table 7. Fatigue endurance limits for various amorphous and crystalline steel filaments"

Composition Sample size UTS Endurance stress Endurance bend, strain Mode and test frequency Reference

(w) (GPa) (MPa) (%I (Hz)

F~~~.sPIz.~CIO 120 2.87 (262) 0.30 bb, 3.2 Hagiwara et al. (1985)

@

Fe-rsSiioBls 0 120 3.40 (483) 0.32 bb, 3.2 Hagiwara et al. (1985)

Fe7~ Si IOB 15 -25 x 1500 - (272) 0.18 br, 1.0 Doi et al. (1981)

Fe75SiloBls 16 x 150 3.20 650 - tt, 30 Baltzer and KUnzi (1987)

Fe69CrlISiloBls 40x 2000 - (-1950) 1.31 bb, 3.2 Hagiwara et al. (1985)

Fe&o 35 x 900 3.45 150 - tt, 5 Frommeyer and Seifert (198 I)

PdsoSi20 -25 x 600 I .34 441 - tt Ogura et al. (1975)

ZrTiCuNiBe bulk 3 x 3 (mm2) 1.90 -60 - bb, 25 Gilbert et al. (1998)

Piano wire 0 120 3.02 (706) 0.39 bb, 3.2 Hagiwara et al. (1985)

sus304 0 120 0.72 (554) 0.42 bb, 3.2 Hagiwara et al. (1985)

sus304 30 x 1000 - (238) 0.18 br, 1.0 Doi et al. (1981)

The test modes are: bb, bending-bending (same direction); br, bending and reversed bending; tt, tension-tension with umin/umax 0. Endurance stresses given in

x

parentheses were calculated from the measured endurance bending strain (= max. strain at the surface). Piano wire (cryst.) has the composition Fe-O.8 wt% C

and the bulk amorphous metal SUS304 is a standard Cr/Ni stainless steel.

a For all materials these limits are attained after IO5 to IO6 cycles.

Ultimate tensile strength.