Page 349 - Finite Element Modeling and Simulations with ANSYS Workbench

P. 349

334 Finite Element Modeling and Simulation with ANSYS Workbench

0.500 2.000

1.000 1.500

All dimensions are in

centimeters.

R6.000

R10.000

R1.500

8.000

10.000

R1.250 2.000

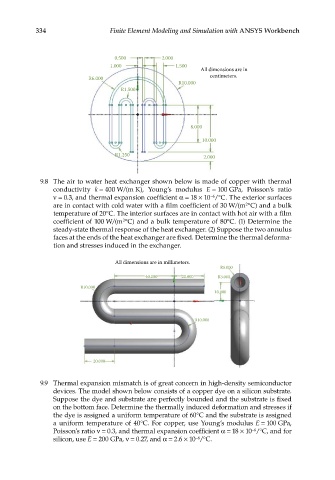

9.8 The air to water heat exchanger shown below is made of copper with thermal

conductivity k = 400 W/(m K), Young’s modulus E = 100 GPa, Poisson’s ratio

ν = 0.3, and thermal expansion coefficient α = 18 × 10 /°C. The exterior surfaces

−6

are in contact with cold water with a film coefficient of 30 W/(m °C) and a bulk

2

temperature of 20°C. The interior surfaces are in contact with hot air with a film

coefficient of 100 W/(m °C) and a bulk temperature of 80°C. (1) Determine the

2

steady-state thermal response of the heat exchanger. (2) Suppose the two annulus

faces at the ends of the heat exchanger are fixed. Determine the thermal deforma-

tion and stresses induced in the exchanger.

All dimensions are in millimeters.

R5.000

40.000 20.000 R3.000

R10.000

10.000

R10.000

20.000

9.9 Thermal expansion mismatch is of great concern in high-density semiconductor

devices. The model shown below consists of a copper dye on a silicon substrate.

Suppose the dye and substrate are perfectly bounded and the substrate is fixed

on the bottom face. Determine the thermally induced deformation and stresses if

the dye is assigned a uniform temperature of 60°C and the substrate is assigned

a uniform temperature of 40°C. For copper, use Young’s modulus E = 100 GPa,

−6

Poisson’s ratio ν = 0.3, and thermal expansion coefficient α = 18 × 10 /°C, and for

silicon, use E = 200 GPa, ν = 0.27, and α = 2.6 × 10 /°C.

−6