Page 213 - Fluid Mechanics and Thermodynamics of Turbomachinery

P. 213

194 Fluid Mechanics, Thermodynamics of Turbomachinery

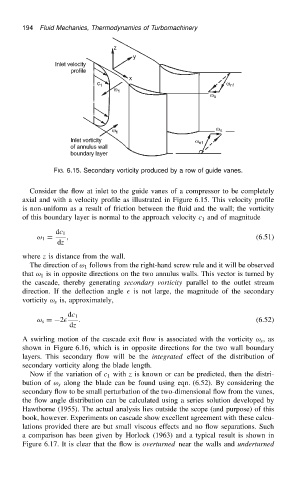

FIG. 6.15. Secondary vorticity produced by a row of guide vanes.

Consider the flow at inlet to the guide vanes of a compressor to be completely

axial and with a velocity profile as illustrated in Figure 6.15. This velocity profile

is non-uniform as a result of friction between the fluid and the wall; the vorticity

of this boundary layer is normal to the approach velocity c 1 and of magnitude

dc 1

ω 1 D , (6.51)

dz

where z is distance from the wall.

The direction of ω 1 follows from the right-hand screw rule and it will be observed

that ω 1 is in opposite directions on the two annulus walls. This vector is turned by

the cascade, thereby generating secondary vorticity parallel to the outlet stream

direction. If the deflection angle is not large, the magnitude of the secondary

vorticity ω s is, approximately,

dc 1

ω s D2 . (6.52)

dz

A swirling motion of the cascade exit flow is associated with the vorticity ω s ,as

shown in Figure 6.16, which is in opposite directions for the two wall boundary

layers. This secondary flow will be the integrated effect of the distribution of

secondary vorticity along the blade length.

Now if the variation of c 1 with z is known or can be predicted, then the distri-

bution of ω s along the blade can be found using eqn. (6.52). By considering the

secondary flow to be small perturbation of the two-dimensional flow from the vanes,

the flow angle distribution can be calculated using a series solution developed by

Hawthorne (1955). The actual analysis lies outside the scope (and purpose) of this

book, however. Experiments on cascade show excellent agreement with these calcu-

lations provided there are but small viscous effects and no flow separations. Such

a comparison has been given by Horlock (1963) and a typical result is shown in

Figure 6.17. It is clear that the flow is overturned near the walls and underturned