Page 220 - Fluid Mechanics and Thermodynamics of Turbomachinery

P. 220

Centrifugal Pumps, Fans and Compressors 201

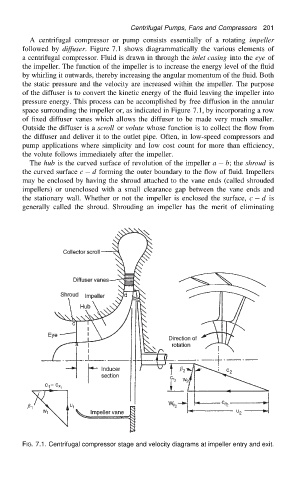

A centrifugal compressor or pump consists essentially of a rotating impeller

followed by diffuser. Figure 7.1 shows diagrammatically the various elements of

a centrifugal compressor. Fluid is drawn in through the inlet casing into the eye of

the impeller. The function of the impeller is to increase the energy level of the fluid

by whirling it outwards, thereby increasing the angular momentum of the fluid. Both

the static pressure and the velocity are increased within the impeller. The purpose

of the diffuser is to convert the kinetic energy of the fluid leaving the impeller into

pressure energy. This process can be accomplished by free diffusion in the annular

space surrounding the impeller or, as indicated in Figure 7.1, by incorporating a row

of fixed diffuser vanes which allows the diffuser to be made very much smaller.

Outside the diffuser is a scroll or volute whose function is to collect the flow from

the diffuser and deliver it to the outlet pipe. Often, in low-speed compressors and

pump applications where simplicity and low cost count for more than efficiency,

the volute follows immediately after the impeller.

The hub is the curved surface of revolution of the impeller a b; the shroud is

the curved surface c d forming the outer boundary to the flow of fluid. Impellers

may be enclosed by having the shroud attached to the vane ends (called shrouded

impellers) or unenclosed with a small clearance gap between the vane ends and

the stationary wall. Whether or not the impeller is enclosed the surface, c d is

generally called the shroud. Shrouding an impeller has the merit of eliminating

FIG. 7.1. Centrifugal compressor stage and velocity diagrams at impeller entry and exit.