Page 221 - Fluid Mechanics and Thermodynamics of Turbomachinery

P. 221

202 Fluid Mechanics, Thermodynamics of Turbomachinery

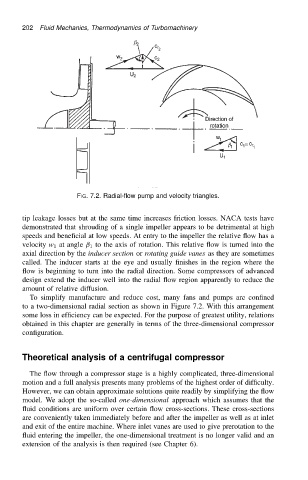

FIG. 7.2. Radial-flow pump and velocity triangles.

tip leakage losses but at the same time increases friction losses. NACA tests have

demonstrated that shrouding of a single impeller appears to be detrimental at high

speeds and beneficial at low speeds. At entry to the impeller the relative flow has a

velocity w 1 at angle ˇ 1 to the axis of rotation. This relative flow is turned into the

axial direction by the inducer section or rotating guide vanes as they are sometimes

called. The inducer starts at the eye and usually finishes in the region where the

flow is beginning to turn into the radial direction. Some compressors of advanced

design extend the inducer well into the radial flow region apparently to reduce the

amount of relative diffusion.

To simplify manufacture and reduce cost, many fans and pumps are confined

to a two-dimensional radial section as shown in Figure 7.2. With this arrangement

some loss in efficiency can be expected. For the purpose of greatest utility, relations

obtained in this chapter are generally in terms of the three-dimensional compressor

configuration.

Theoretical analysis of a centrifugal compressor

The flow through a compressor stage is a highly complicated, three-dimensional

motion and a full analysis presents many problems of the highest order of difficulty.

However, we can obtain approximate solutions quite readily by simplifying the flow

model. We adopt the so-called one-dimensional approach which assumes that the

fluid conditions are uniform over certain flow cross-sections. These cross-sections

are conveniently taken immediately before and after the impeller as well as at inlet

and exit of the entire machine. Where inlet vanes are used to give prerotation to the

fluid entering the impeller, the one-dimensional treatment is no longer valid and an

extension of the analysis is then required (see Chapter 6).