Page 256 - Fluid Mechanics and Thermodynamics of Turbomachinery

P. 256

Radial Flow Gas Turbines 237

.2/

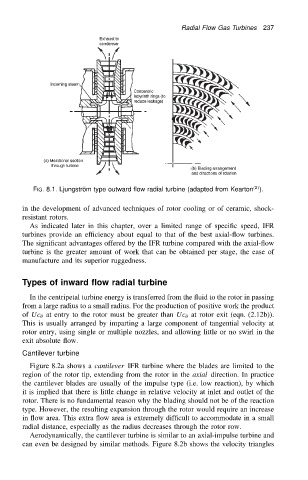

FIG. 8.1. Ljungstr¨ om type outward flow radial turbine (adapted from Kearton ).

in the development of advanced techniques of rotor cooling or of ceramic, shock-

resistant rotors.

As indicated later in this chapter, over a limited range of specific speed, IFR

turbines provide an efficiency about equal to that of the best axial-flow turbines.

The significant advantages offered by the IFR turbine compared with the axial-flow

turbine is the greater amount of work that can be obtained per stage, the ease of

manufacture and its superior ruggedness.

Types of inward flow radial turbine

In the centripetal turbine energy is transferred from the fluid to the rotor in passing

from a large radius to a small radius. For the production of positive work the product

of Uc at entry to the rotor must be greater than Uc at rotor exit (eqn. (2.12b)).

This is usually arranged by imparting a large component of tangential velocity at

rotor entry, using single or multiple nozzles, and allowing little or no swirl in the

exit absolute flow.

Cantilever turbine

Figure 8.2a shows a cantilever IFR turbine where the blades are limited to the

region of the rotor tip, extending from the rotor in the axial direction. In practice

the cantilever blades are usually of the impulse type (i.e. low reaction), by which

it is implied that there is little change in relative velocity at inlet and outlet of the

rotor. There is no fundamental reason why the blading should not be of the reaction

type. However, the resulting expansion through the rotor would require an increase

in flow area. This extra flow area is extremely difficult to accommodate in a small

radial distance, especially as the radius decreases through the rotor row.

Aerodynamically, the cantilever turbine is similar to an axial-impulse turbine and

can even be designed by similar methods. Figure 8.2b shows the velocity triangles