Page 316 - Fluid Mechanics and Thermodynamics of Turbomachinery

P. 316

Hydraulic Turbines 297

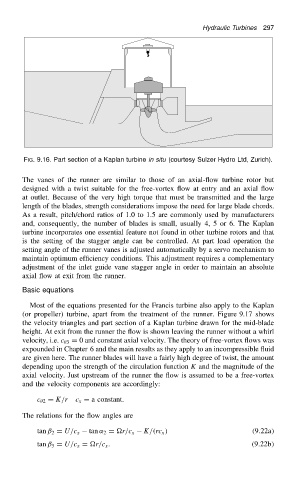

FIG. 9.16. Part section of a Kaplan turbine in situ (courtesy Sulzer Hydro Ltd, Zurich).

The vanes of the runner are similar to those of an axial-flow turbine rotor but

designed with a twist suitable for the free-vortex flow at entry and an axial flow

at outlet. Because of the very high torque that must be transmitted and the large

length of the blades, strength considerations impose the need for large blade chords.

As a result, pitch/chord ratios of 1.0 to 1.5 are commonly used by manufacturers

and, consequently, the number of blades is small, usually 4, 5 or 6. The Kaplan

turbine incorporates one essential feature not found in other turbine rotors and that

is the setting of the stagger angle can be controlled. At part load operation the

setting angle of the runner vanes is adjusted automatically by a servo mechanism to

maintain optimum efficiency conditions. This adjustment requires a complementary

adjustment of the inlet guide vane stagger angle in order to maintain an absolute

axial flow at exit from the runner.

Basic equations

Most of the equations presented for the Francis turbine also apply to the Kaplan

(or propeller) turbine, apart from the treatment of the runner. Figure 9.17 shows

the velocity triangles and part section of a Kaplan turbine drawn for the mid-blade

height. At exit from the runner the flow is shown leaving the runner without a whirl

velocity, i.e. c 3 D 0 and constant axial velocity. The theory of free-vortex flows was

expounded in Chapter 6 and the main results as they apply to an incompressible fluid

are given here. The runner blades will have a fairly high degree of twist, the amount

depending upon the strength of the circulation function K and the magnitude of the

axial velocity. Just upstream of the runner the flow is assumed to be a free-vortex

and the velocity components are accordingly:

c 2 D K/r c x D a constant.

The relations for the flow angles are

K/.rc x / .9.22a/

tan ˇ 2 D U/c x tan ˛ 2 D r/c x

tan ˇ 3 D U/c x D r/c x . .9.22b/