Page 144 - Fluid Power Engineering

P. 144

118 Cha pte r F o u r

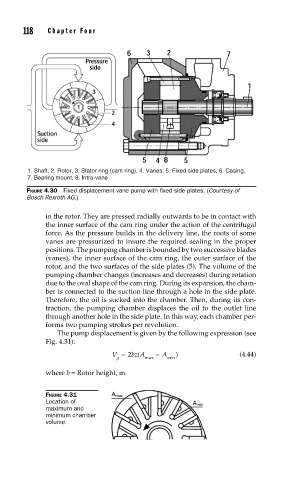

1. Shaft, 2. Rotor, 3. Stator ring (cam ring), 4. Vanes, 5. Fixed side plates, 6. Casing,

7. Bearing mount, 8. Intra-vane

FIGURE 4.30 Fixed displacement vane pump with fi xed side plates. (Courtesy of

Bosch Rexroth AG.)

in the rotor. They are pressed radially outwards to be in contact with

the inner surface of the cam ring under the action of the centrifugal

force. As the pressure builds in the delivery line, the roots of some

vanes are pressurized to insure the required sealing in the proper

positions. The pumping chamber is bounded by two successive blades

(vanes), the inner surface of the cam ring, the outer surface of the

rotor, and the two surfaces of the side plates (5). The volume of the

pumping chamber changes (increases and decreases) during rotation

due to the oval shape of the cam ring. During its expansion, the cham-

ber is connected to the suction line through a hole in the side plate.

Therefore, the oil is sucked into the chamber. Then, during its con-

traction, the pumping chamber displaces the oil to the outlet line

through another hole in the side plate. In this way, each chamber per-

forms two pumping strokes per revolution.

The pump displacement is given by the following expression (see

Fig. 4.31):

V = 2 bz A − A ) (4.44)

(

g max min

where b = Rotor height, m.

FIGURE 4.31

Location of

maximum and

minimum chamber

volume.