Page 149 - Fluid Power Engineering

P. 149

Hydraulic Pumps 123

• Hydraulic servo controllers, for closed-loop control of the pump

displacement

• Electrohydraulic proportional controllers, for open-loop control

of the pump displacement

• Electrohydraulic servo controllers, for open- and closed-loop

control of the pump displacement

4.7.2 Pressure-Compensated Vane Pumps

Construction and Operation

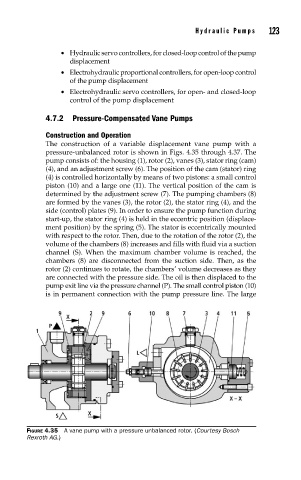

The construction of a variable displacement vane pump with a

pressure-unbalanced rotor is shown in Figs. 4.35 through 4.37. The

pump consists of: the housing (1), rotor (2), vanes (3), stator ring (cam)

(4), and an adjustment screw (6). The position of the cam (stator) ring

(4) is controlled horizontally by means of two pistons: a small control

piston (10) and a large one (11). The vertical position of the cam is

determined by the adjustment screw (7). The pumping chambers (8)

are formed by the vanes (3), the rotor (2), the stator ring (4), and the

side (control) plates (9). In order to ensure the pump function during

start-up, the stator ring (4) is held in the eccentric position (displace-

ment position) by the spring (5). The stator is eccentrically mounted

with respect to the rotor. Then, due to the rotation of the rotor (2), the

volume of the chambers (8) increases and fills with fluid via a suction

channel (S). When the maximum chamber volume is reached, the

chambers (8) are disconnected from the suction side. Then, as the

rotor (2) continues to rotate, the chambers’ volume decreases as they

are connected with the pressure side. The oil is then displaced to the

pump exit line via the pressure channel (P). The small control piston (10)

is in permanent connection with the pump pressure line. The large

FIGURE 4.35 A vane pump with a pressure unbalanced rotor. (Courtesy Bosch

Rexroth AG.)