Page 154 - Fluid Power Engineering

P. 154

128 Cha pte r F o u r

• Point 2 can be displaced horizontally by means of the adjust-

ment spring setting, and displaced vertically by using the maxi-

mum inclination angle limiter.

• The slope of line 2–3 is imposed by the stiffness of the first

control spring, while that of line 3–4 is determined by the

summation of stiffness of both of the first and second control

springs.

• The operation in the vicinity of point 3 does not consume the

whole available power of the prime mover due to the straight

line approximation of the constant power curve. But the

simplicity and relative lower cost give good appreciation to

this design. However, other power controllers are commercially

available, which better agree with the constant power curve.

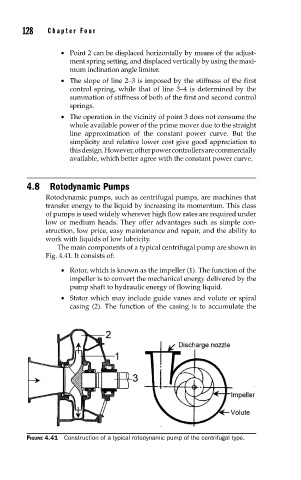

4.8 Rotodynamic Pumps

Rotodynamic pumps, such as centrifugal pumps, are machines that

transfer energy to the liquid by increasing its momentum. This class

of pumps is used widely wherever high flow rates are required under

low or medium heads. They offer advantages such as simple con-

struction, low price, easy maintenance and repair, and the ability to

work with liquids of low lubricity.

The main components of a typical centrifugal pump are shown in

Fig. 4.41. It consists of:

• Rotor, which is known as the impeller (1). The function of the

impeller is to convert the mechanical energy delivered by the

pump shaft to hydraulic energy of flowing liquid.

• Stator which may include guide vanes and volute or spiral

casing (2). The function of the casing is to accumulate the

FIGURE 4.41 Construction of a typical rotodynamic pump of the centrifugal type.