Page 152 - Fluid Power Engineering

P. 152

126 Cha pte r F o u r

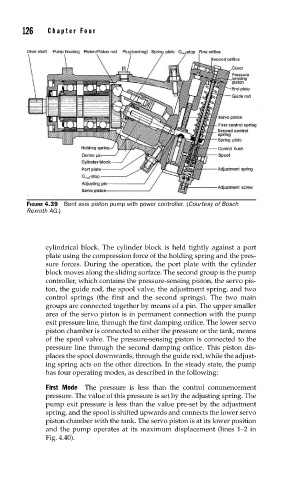

FIGURE 4.39 Bent axis piston pump with power controller. (Courtesy of Bosch

Rexroth AG.)

cylindrical block. The cylinder block is held tightly against a port

plate using the compression force of the holding spring and the pres-

sure forces. During the operation, the port plate with the cylinder

block moves along the sliding surface. The second group is the pump

controller, which contains the pressure-sensing piston, the servo pis-

ton, the guide rod, the spool valve, the adjustment spring, and two

control springs (the first and the second springs). The two main

groups are connected together by means of a pin. The upper smaller

area of the servo piston is in permanent connection with the pump

exit pressure line, through the first damping orifice. The lower servo

piston chamber is connected to either the pressure or the tank, means

of the spool valve. The pressure-sensing piston is connected to the

pressure line through the second damping orifice. This piston dis-

places the spool downwards, through the guide rod, while the adjust-

ing spring acts on the other direction. In the steady state, the pump

has four operating modes, as described in the following:

First Mode The pressure is less than the control commencement

pressure. The value of this pressure is set by the adjusting spring. The

pump exit pressure is less than the value pre-set by the adjustment

spring, and the spool is shifted upwards and connects the lower servo

piston chamber with the tank. The servo piston is at its lower position

and the pump operates at its maximum displacement (lines 1–2 in

Fig. 4.40).