Page 145 - Fluid Power Engineering

P. 145

Hydraulic Pumps 119

Due to the oval shape, the pump construction is axi-symmetrical.

There are two pressure and two suction chambers opposite each other.

Therefore, the rotor is pressure balanced. It is loaded mainly by the

pump driving torque. In this way, the bearing load is minimized,

which reduces the friction and wear and increases the pump efficiency

and service life.

Side Clearance Leakage

The internal leakage in vane pumps takes place, mainly, through the

rotor side clearance and blade tip clearance. In the case of fixed side

plates, the side clearance leakage is uncontrollable. The wear of the

fixed side plates is not compensated for, which increases the internal

leakage. By using movable side plates, it is possible to:

• Minimize the side clearance leakage

• Compensate for the heat expansion of the rotor

• Act against sudden pressure changes

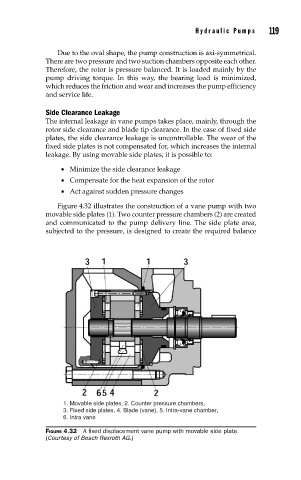

Figure 4.32 illustrates the construction of a vane pump with two

movable side plates (1). Two counter pressure chambers (2) are created

and communicated to the pump delivery line. The side plate area,

subjected to the pressure, is designed to create the required balance

1. Movable side plates, 2. Counter pressure chambers,

3. Fixed side plates, 4. Blade (vane), 5. Intra-vane chamber,

6. Intra vane

FIGURE 4.32 A fi xed displacement vane pump with movable side plate.

(Courtesy of Bosch Rexroth AG.)