Page 141 - Fluid Power Engineering

P. 141

Hydraulic Pumps 115

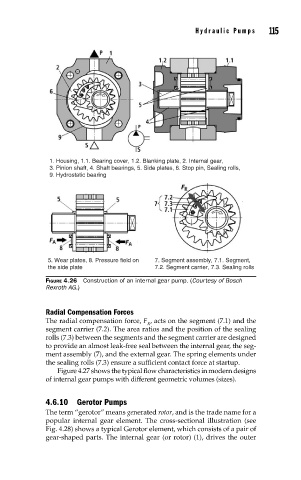

1. Housing, 1.1. Bearing cover, 1.2. Blanking plate, 2. Internal gear,

3. Pinion shaft, 4. Shaft bearings, 5. Side plates, 6. Stop pin, Sealing rolls,

9. Hydrostatic bearing

5. Wear plates, 8. Pressure field on 7. Segment assembly, 7.1. Segment,

the side plate 7.2. Segment carrier, 7.3. Sealing rolls

FIGURE 4.26 Construction of an internal gear pump. (Courtesy of Bosch

Rexroth AG.)

Radial Compensation Forces

The radial compensation force, F , acts on the segment (7.1) and the

R

segment carrier (7.2). The area ratios and the position of the sealing

rolls (7.3) between the segments and the segment carrier are designed

to provide an almost leak-free seal between the internal gear, the seg-

ment assembly (7), and the external gear. The spring elements under

the sealing rolls (7.3) ensure a sufficient contact force at startup.

Figure 4.27 shows the typical flow characteristics in modern designs

of internal gear pumps with different geometric volumes (sizes).

4.6.10 Gerotor Pumps

The term “gerotor” means generated rotor, and is the trade name for a

popular internal gear element. The cross-sectional illustration (see

Fig. 4.28) shows a typical Gerotor element, which consists of a pair of

gear-shaped parts. The internal gear (or rotor) (1), drives the outer